1.1 Supervision of concrete pours is essential to achieving the level tolerances required.

1.2 Concrete placement and finish is easily the most significant trade to regularly FAIL to provide the required finishes and are typically the first to blame everyone else – formwork, reinforcement, the sun, the rain, the wind – anything really. They are the first to sit around and put their hand out for a carton of beer to do something that is expected of them as a part of their contract/as a part of “good tradesman like” works/as expected of them under the Australian standards – which most have either not seen, not read, not understood or just don’t care because they have been allowed get away with substandard workmanship job after job.

1.3 Quite simply – we need to spend far more time with this trade to control the outcome – to be more vigilant on what they deliver to us.

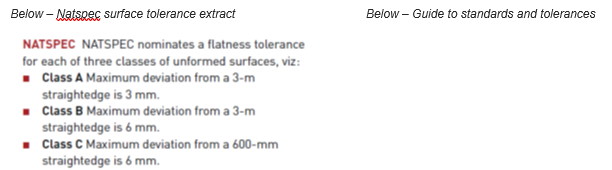

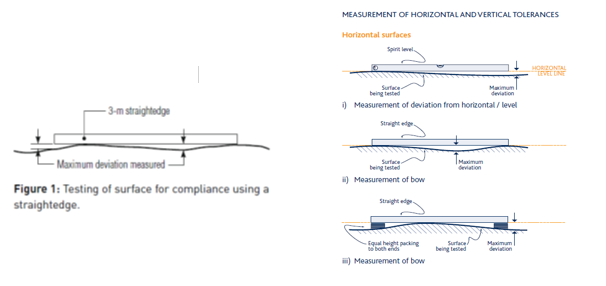

1.4 Ensure that the project specification and finishes schedule is reviewed to confirm the standard of finish expected of exposed and concealed, formed and unformed surfaces. It is important to note that some projects require a much greater standard of finish and tolerance than the Australian standard – super flat factory floors, some shopping areas floors and so on. There is no single standard for the tolerances required for a project. AS 3600 relates to the quality of the concrete and maximum tolerances allowed for unformed elements, AS3610 provides formed surfaces tolerances and techniques for measuring this which may be useful in assessing surface finishes – and then there are specifications such as NATSPEC which are commonly used that provide a simple specification for surface finishes. Note: The contract can overrule the standard or BCA/NCC if the standard is greater than the Code. Remember the BCA/AS is a minimum standard; the contract may require a standard in-excess or better that the standard or it may even specify BEST PRACTICE STANDARD. Know what you are contracted to achieve as well as what the Code requires.

1.5 Many projects will specify a 3mm in 3m straight edge rule – even if this is not acceptable for the applied finishes.

1.6 The applied floor finish – long lengths of timber flooring – or large format (size) tiles – will dictate the quality of finish required as well regardless of the specification – and this needs to be identified to the concreter prior to contract/pouring.

1.7 Waterproofing membrane substrate also has a standard that needs to be achieved – see Ardex advice at the end of this policy + refer waterproofing policies

1.8 The other aspect is achieving correct falls on podiums, balconies, plant decks etc - which are not guided by any standard – but the ponding of water is a sure sign the work is not as required.

1.9 To understand what is required of a floor –In layman’s terms;

SURFACE FINISH – Quality of the visible surface where exposed such as blemished or ‘bony’

SURFACE LEVEL – Allowable vertical difference of the surface from a fixed datum

SURFACE FLATNESS – Variance of a surface level between two points