1.1 Waterproof all plant rooms and grade to a drain point of discharge. Provide an overflow point that accommodates a Q100 event where exposed to the weather or as a minimum equal to the capacity of the drainage point. Both need to be designed by a hydraulic engineer.

1.2 Equipment must be installed on suitable isolation mountings to ensure the movement of the equipment does not damage the waterproofing membrane and does not transfer noise or vibration through the slab and structure. Non isolated vibration can and often does transform in to amplified noise as it travels through the structure, particularly steel and concrete which conduct noise/vibration.

1.3 Isolate all compressor and units / extractors or fans with moving parts. 1 compressor may have run at 35 decibels which is below acceptable levels. Put 20 compressors on the roof running at 35 decibels with no isolation and you have a problem. Do not let the Mechanical installer convince you that the units do not need isolation as they are below legislated levels. All come with rubber or spring mounts so make sure they are used, not left on the floor under the install.

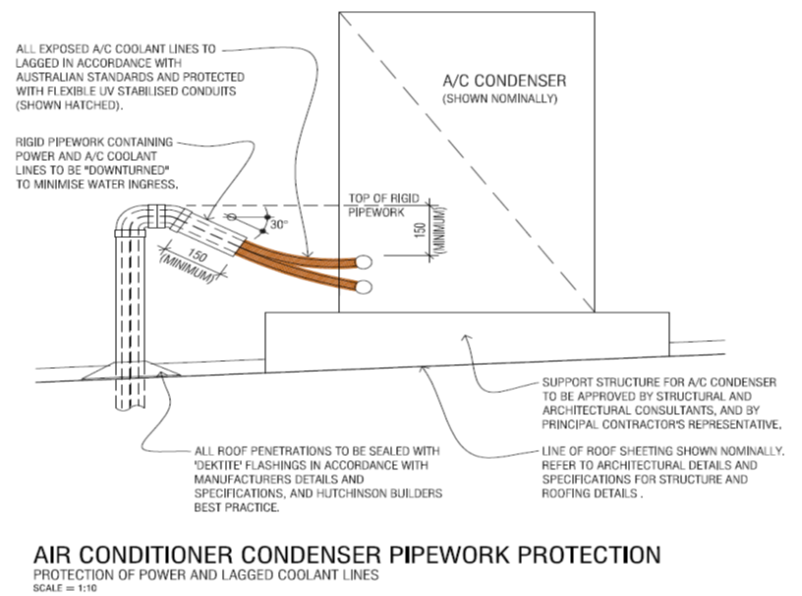

1.4 All Roof & Wall penetrations are a source of potential leaks and are to be constructed in accordance with Roofing Quality Handbook.

1.5 External lagging is to be mechanically protected from damage and UV exposure (note – “mechanically” means physically covered in a hard product/flashing preferably suitable metal or UV stabilised plastic)

Above – Colourbond flashings as mechanical and UV protection for roof mounted services

Above - refer rear of the policy for the full size drawing