1.1 Water damage to surrounding areas is a major issue and source of defects/costs (normally associated with above podium/multistorey – or best described as “suspended” pools)

1.2 With recent but long term policy for water restrictions/expensive water supply rates and automatic top up valves required on many projects - In-ground pools have become a major dispute area for leaks due to the discovery of substantial water loss either through a spike in very expensive chemical costs (a rise in chemicals due to the need to the loss of treated water through a leak chemically treat the new “topped up” water) , or worse - on arrival of the first post leak water rates bill – showing a tap has been running full time for 3 months.

1.3 Leaks in pools typically come from a number of sources and require some simple preventative steps;

1.3.1 Swimming pools will not be constructed over control joints in podium or any slabs.

1.3.2 Pool sub-shells are required to be waterproofed in accordance with AS4654.2, but will not be waterproofed, unless the all penetration and joints are filled and adequate bond-breakers are installed. No holes, penetration, cracks or junctions are too evident in the pool prior to waterproofing.

1.3.3 No post construction holes are to be installed in the sub-shell under any circumstances.

1.3.4 The pool sprayed shell will also be waterproofed prior to installation of the pool liner.

1.3.5 The pool liner and membrane shall be verified for compatibility and confirmed in writing by the manufacturers.

1.3.6 Pool shell and sub-shell junctions at coping level are to be detailed and bond-broken prior to waterproofing.

1.3.7 Coping tiles must not bridge the junction between the shell and sub-shell under any circumstances.

1.3.8 Please note: AS3958.1 does not permit the use of mesh backed Mosaic tiles and some mesh backed tiles in any outdoor areas or in a submersed location unless the adhesive and waterproofing and adhesive is specifically designed and tested for such installations. Contact Mapei for further information as they have an approved system for mesh backed tiles, however these is very limited waterproofing systems permitted with this adhesive system.

1.3.9 All pools are to contain a waterproofed hob at the edge of the pool shell to prevent the migration of water through the tiling/bed and affecting the pool tiles and leaching calcium at or above pool water level.

1.3.10 Control joints must be installed to coping pavers and tiles at 2.4m centres maximum, at all corners, at 1.2m centres on curves and a full perimeter control joint must be installed between the coping and the paving abutting the coping. All joints must be full depth tile and adhesive. Refer to AS3958.1 for specific details.

"Movement joints should be inserted to coincide with the structural junction of the pool shell and the surround slab and where pool surround tiling abuts walls, drainage channels and other features. Intermediate movement joints should be inserted at intervals of 6 m or less, except for mosaics where they are not required.

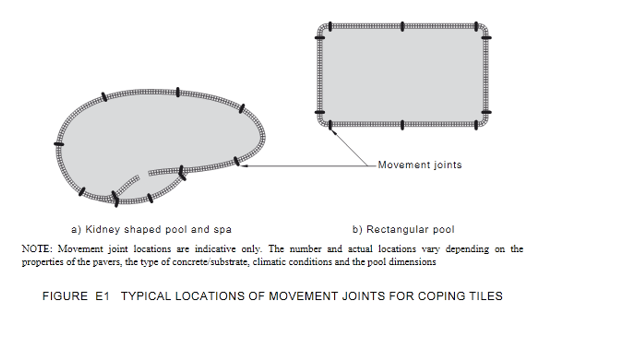

For coping, movement joints are recommended at intervals of 3 m, with a maximum of 4.5 min (see Figure E1).

1.3.11 Able flex must be installed to the perimeter of all topping slabs or bedding materials surrounding the pool to allow for expansion of the substrate. This must be the full depth of the slab or bedding.

1.3.12 Skimmer boxes must be marked with a maximum level line.

1.3.13 All pools will be installed with a self-levelling drain.

1.3.14 Pools shells must be cured prior to the installation of the internal liner. Refer to the moisture policy with respect to moisture content within the pool prior to installing the liner.

1.3.15 Pool fencing must not be cored in the slab/tiles without reinstatement of the waterproofing. All cores must be epoxy fill to the finished surface level of the paving. Pool fencing must comply with AS1928 and Pool Safety Council Requirements.

1.3.16 All pipework installed to operate the pool must be pressure tested prior to filling of the pool.

1.3.17 Pool voids constructed over habitable or non-habitable used areas must be waterproofed in accordance with the podium waterproofing provisions.

1.3.18 Pool lights should be waterproof – IP 68 rated with a length of 12 volt cable in the fitting to allow the fitting to be removed and replaced/repaired out of the water. The light will have a cast in shroud where built into walls, with the light fitting itself installed after the pebblecrete is complete. The fitting should have a built in escutcheon plate to cover the finishes (particularly where tiled)

Above - Cast in light shroud

Above - a different type of light – with insufficient flange design for a satisfactory finish over mosaic tiles – this is a light suitable for pebblecrete only – which one has your “expert consultant” picked for your job?