1.1 Windows are only waterproof to certain extent. Like a roof they are designed to resist a large amount of water (in this case with seals to an engineered level of allowable water penetration/structural failure), but they are principally to collect and remove water. Rain falls via gravity but it is driven onto windows by wind pressure and run off from other façade elements onto the window.

1.2 Windows are also required to be washed and reasonably maintained. This may also mean windows installed fully or partially protected may need to be provided with similar weathering as fully or partially exposed windows. Manufacturers maintenance procedures must be provide at the time of handover to avoid both deterioration and window leakage due to high pressure cleaning. Windows must never be cleaned using pressure hose or any method water application capable of 120kpa or greater.

1.3 As the wind pressure conditions increase, water will penetrate the window seals which are the flexible connection of the “flexible” glass and the stiff aluminium of the window frame and joints in the aluminium joinery. The movable framing also flexes at the junction between the tracks and the moveable panel which is sealed using felt seals which allows the window to be dust/wind sealed, but do not prevent water entry completely. Windows should be sealed to provide pressure equalisation within the window assembly and installation.

1.4 As a result of the multiple locations where water can penetrate a window, the entire window frame sits over a sill that has drainage holes to allow any water to drain to the outside. A good window design provides an initial seal or primary weathering / barrier that diverts most of the water away from the window and a waterproof/sealed connection to the building is the secondary line of defence against water ingress.

1.5 The simple concept is to provide an initial seal/barrier against water entry into the building, but have a backup drained solution for the window, so any water that beats the initial seals, falls into a drainage channel which overflows back outside the building. Clause Heading 1

1.6 In terms of suitability for location – windows are an engineered and tested product. They must be designed and certified to meet wind pressures for the design of building and location of building as determined by the project engineer based on the Building Code of Australia. (Typical extract shown right).

A window system is tested to a wind and water penetration rating in a wind tunnel. The window is required to be fabricated and installed in accordance with engineered and tested detail as a minimum requirement to compliance with the BCA/NCC. In addition to this AS2047 provides serviceability, engineering requirements and water penetration ratings (which are the basis of the window design i.e. Very important).

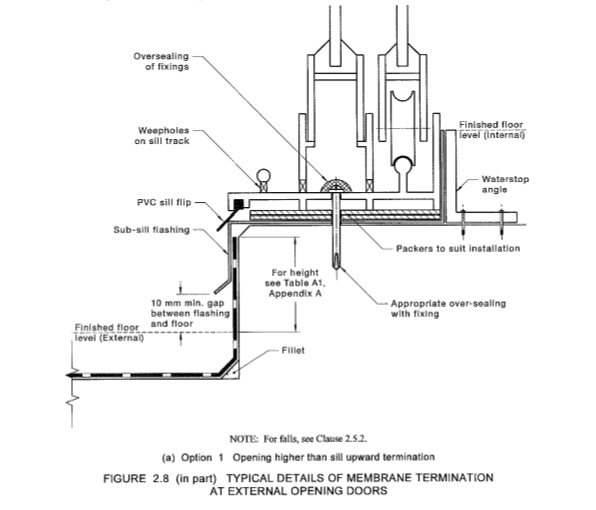

In addition to this AS 4654.2 (External Waterproofing Standard) requires minimum heights between internal and external floor levels across doors and water stop angles/waterproof membranes to ensure windows and doors are suitable waterproofed. See extract below. Read the Standard.

2.8.3 Doors and windows onto external waterproofed areas

For doors and windows onto external waterproofed areas, the following apply;

a) Sub-sill flashing shall be included as part of the membrane system (see Note 1).

b) Where the internal and external finished floor levels do not allow an upturn, the membrane shall be fixed under the sill and terminate in the stormwater system (see Note 2).

NOTES

- For typical detail of sub-sill flashing, See Figure 2.8

- For typical detail of membrane fixed under the sill and terminating in the stormwater system, see Figure 2.9

-

- Ideally, the deck surface should fall away from the grate, and additionally the grate should be to the width of or greater than the opening.

- Typicaldetails of external terminations at external opening doors and at wall openings are shown in Figure 2.8 and Figure 2.9.

- Openings should be provided with a set-down or hob to provide a vertical surface of sufficient dimensions. see also Table A1, Appendix A.

- Where circumstances do not permit the inclusion of a set-down or hob (e.g. for wheelchair access), a gutter should be formed into the substrate immediately in front of the opening.

- Requirments for fixings to seals and frames are given in AS 2047.

1.7 Ensure that the design wind rating is obtained for the site and included in the specification of the system to be implemented prior to procurement. This can have a dramatic effect on the type of system suitable to the application and therefore the cost which means early identification is crucial. Once this rating is established and provided to the Manufacturer, obtain documentation which states that windows and installation procedure quoted complies with this wind rating (BCA/NCC).