10.1 Timber flooring will not be used on bathroom floors.

10.2 Structural timber flooring will be sheeted with a FC sheet tile underlay or compressed sheet floor prior to any bedding or tiling.

10.3 Non-Durable materials are not to be in contact with the floor in bathrooms, WC’s or Laundries. All skirtings, door frames, architraves, sinks, vanity units or non-durable materials will be installed 5mm clear of the finished floor level or waterproofed 125 mm above tile finished level.

10.4 The 5mm gap is to be sealed with a coloured non-moulding sealant (Tile and bathroom coloured silicone).

10.5 Check finishes are suitable for the area – conduct stain testing on tiles, stone etc.

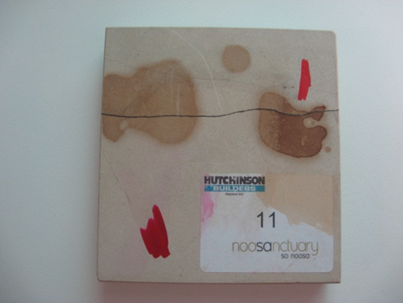

10.6 Above – stain testing of the proposed limestone bench top using lipstick, red wine, acetone, and coffee - even with a quality sealer this product was not suitable and was not used

10.7 Frameless glass mirrors are not an acceptable risk to be taken on by Hutchinson Builders. They have a tendency for the silvering to fail around the perimeter. (See photo below). Frameless mirrors in wet areas are never permitted without prior approval of the Team Leader

10.8 This may be reduced through the use of a vinyl backing over the painted silvering that gives mirrors their reflective properties. Preference is for edges of mirrors to be framed to conceal this often unavoidable problem.

10.9 Consult your designer where frameless mirrors or splashbacks are specified to review outcomes. Get written acceptance of risk transfer from the Owner where frames are not preferred.

10.10 Shower screens are to be built to meet the requirements of AS3740 for detailing and AS1288 for the glass installation and ;

10.10.1 Ensure noggings/supports are provided in walls for the shower screen locations

10.10.2 Ensure the screen doesn’t open onto taps in the shower – or joinery/toilets etc outside the shower.

10.10.3 Frameless, semi frameless and framed shower screen installations may differ but the principle remains the same – to contain the water in the shower (or bath). Frameless installations require a flexible seal to the doors, and fixed panels sealed to the tiles it abuts. Framed construction requires the OUTSIDE of the frame sealed – but the inside UNSEALED (refer section 4.8).

10.10.4 Frameless shower screens are required to have a 3mm minimum gap to each side to prevent the glass door hitting the fixed panels – refer AS 1288 (see annexure to policy for extract).

10.11 Typical frameless shower screen arrangement – threshold angle, frameless glass door with the flexible bottom seal.