- 3 Minutes to read

- Print

- PDF

2. Movement

- 3 Minutes to read

- Print

- PDF

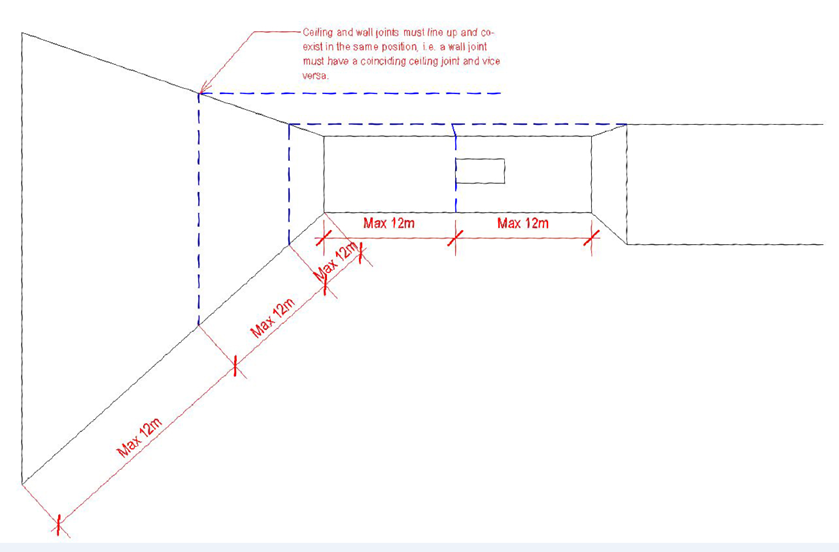

2.1 Structures of all types have the need for movement - for example – typically there are movement joints are required at 8m centres maximum for unreinforced blocks and 16m maximum for reinforced blocks. Plasterboard is at 12m maximum centres.

2.2 Materials of all types move due to temperature fluctuations, moisture content changes. Many materials move at different rates (differential movement). It is imperative that control joints be located to BEST practice which does not mean sparingly or where the installer “feels” like it.

2.3 Plasterboard is not designed to withstand stress due to structural movement or excessive changes in temperature or humidity, and are required to be constructed with movement (control) joints – in walls, ceilings and external soffits.

2.4 Many tens of thousands of dollars are spent every year on repairing failed linings where control joints have not been provided or not constructed correctly. Most of the cost is working on a completed building – out of hours works, scaffolding /scissors /booms for high walls and soffits (and sometimes craneage of same), protection of other finished surfaces in the completed building, repainting and piecemeal work (which is NON contract and therefore a NON competitive cost).

2.5 The additional cost of putting the control joint in after the fact is ridiculously more expensive than ensuring that the correct placement and construction of joints is provided the first time.

2.6 In smaller buildings it is critical to know the soil class to predict the expected movement to ensure the joints are installed top cater for the expected movement.

Below– no control joints in this 20m long wall – control joint required at max 12m centres. It costs MORE to do it at this stage- even more again if the building is occupied.

Walls and Ceilings

2.7 Control joints in internal plasterboard walls and ceilings MUST be constructed ;

• directly over all control joints in the structure,

• at maximum 12m intervals in both directions,

• at every change in material (e.g plasterboard to villaboard),

• at every change in substrate material (e.g block wall butting into a concrete column for example),

• at all re-entrant corners in the ceiling,

• by utilising floor to ceiling openings as control joints,

• at each storey/level (stairwells etc),

• at floors - Plaster sheets will contain a 10mm gap at floor level to cater for vertical expansion/movement, and

• on non-loadbearing walls at heads (using a deflection track).

2.8 Fit battens, studs or joists on BOTH sides of the control joint - spaced slightly apart in the frame - at ALL control joint locations.

2.9 All joints, junctions and penetrations in the sheets will be set and mastic sealed as per approved details (unless a flexible preformed moulding is used).

2.10 For a sealant to be effective for control joints it must have the following properties:

• Good flexibility, elastic set,

• Low hardness,

• Excellent adhesion, usually to concrete, timber, plaster and galvanised steel,

• Minimal shrinkage (less than 5%),

• Moderate density (greater than 800kg/M3) ,

• Fire rated where required (and certified), and

• NEVER USE NO MORE GAPS or Foam a fill or anything like this.

2.11 Reference should be made to the manufacturer’s recommendations to ensure the particular type or grade of sealant is suitable for the purpose.

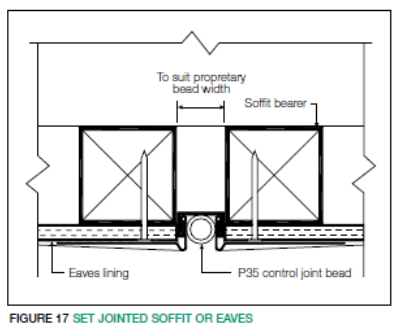

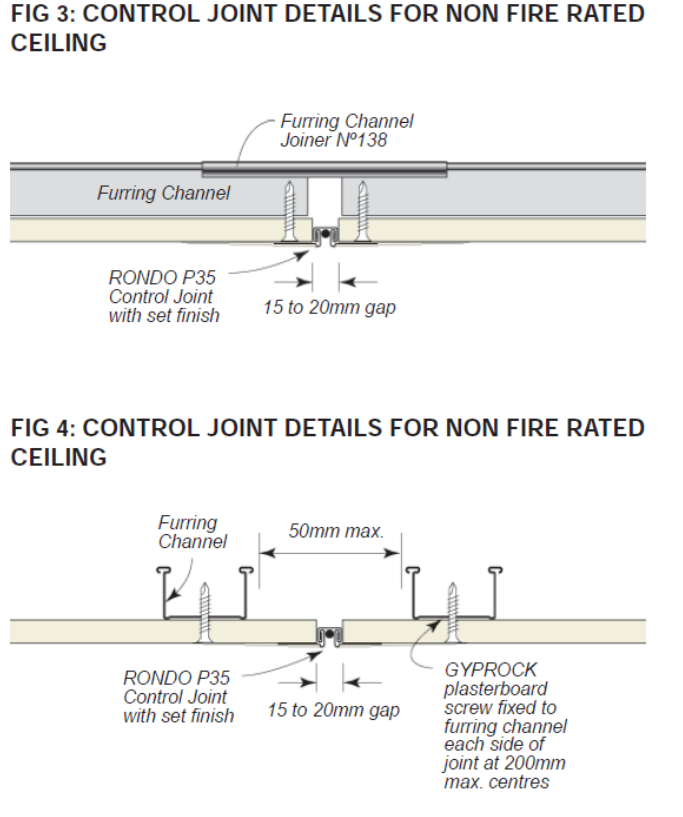

2.12 Typical CEILING control joints

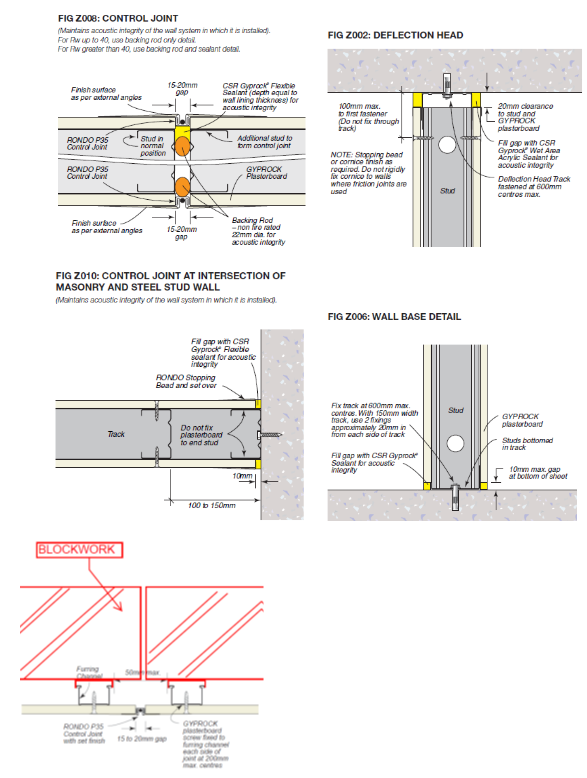

2.13 Typical WALL control joint details

Typical battened external wall control joint

External Sofifits

2.14 To be constructed using same principles as internal wall/ceiling movement joint details – but construct to manufacturers requirements for wind pressures etc (being located externally).

2.15 Note that set external soffit linings must ONLY be used with INSULATED roofing. We do not allow non-insulated roof areas to be constructed with set joints.

a) Eaves;

i) For long narrorw eaves with butt jointed sheeting located at approximately 10m spacings.

ii) For eaves located opposite vertical movement joints in HardiTex base sheet clad construction.

b) Soffits:

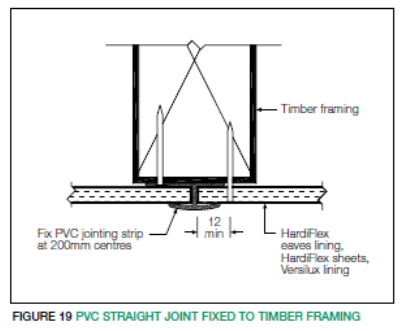

i) Non-set soffits. A0.5mm gap between sheets is recommended.

ii) Set soffits. For set soffits, a 2mm to 6mm control joint located at 4.2m maximum spaces is recomended.

Where control jointing is a Villaboard lining installation is not acceptable at 4.2m spacings, a bay configuration as shown in Figure 12 can be considered, with provision for movement at the bay perimeter.

Framing membranes to which the Villaboard lining is fixed must not continue across this control joint at the bay perimeter.

iii) Soffits directly under metal roofing. For soffits directly under metal roofing, Versilux sheets are recommended.

Where Villaboard lining is used:

For insulated roofs the maximum spacing for a control joint is 3.6m.

For uninsulated roofs the maximum spacing for a control joint is 2.4m as shown in Figure 13.