2.1 Waterproofing selection will be from the below suppliers unless authorised by the team leader

• Chemind – 07 32555755

www.chemind.com.au

• Sika – 07 36339222

https://aus.sika.com/

• Bayset 07 32195899

www.bayset.com.au

• Parchem – 07 39022300

www.parchem.com.au

• Ardex - 07 38176000

https://ardexaustralia.com/

• Tremco - 07 38899222

www.tremco.com.au

2.2 Waterproofing systems are essentially available in 5 systems;

2.2.1 Liquid membranes wet mix membranes in 20 litre drums that are brush/roller applied to the surface - susceptible to thickness variations in application –and may be either;

• Acrylic based (compatible with render)

• Bitumen based (not suitable for render or tiling over)

• Polyurethane based (not suitable for render or finishes)

2.2.2 Sheet membrane – bitumen based.

2.2.3 Additives –

• Admixtures added to the concrete during batching at the plant - TAM, Xypex and so on - susceptible to excessive cracking when used in external areas like podiums etc.

• Surface applied additives – TAM, Xypex DS1 – dry shake additives – applied during the pour and power trowelled into the surface. Good secondary waterproofing system that is immediately effective where the membrane will not be applied for some time but you need waterproofing in place – looks a little like a carborundum surface.

2.2.4 Plug’s – grout based additive product to “plug” up around pipe penetrations, wall/floor joints etc.

2.2.5 Injection systems – for repairing leaks where the membrane is not readily accessible.

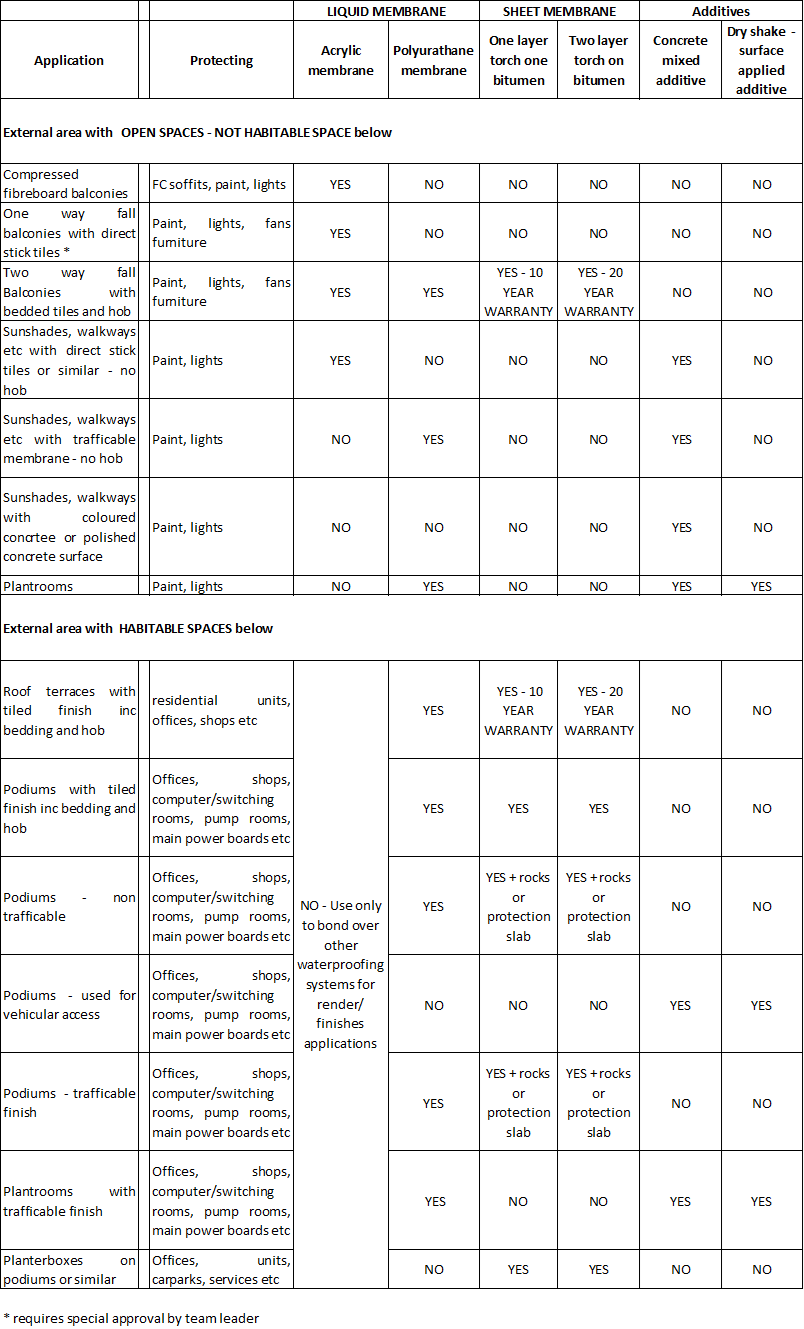

2.3 Because of different finishes and risks for different external areas, there is no “one” solution - Refer next page for a clear list on what systems are suitable for application.

2.4 Determine all detailing of the waterproofing terminations to finishes etc – where over flashings are not acceptable, use a bandaged termination detail - ensure all proposed materials are compatible with each other and with the proposed finishes.

2.5 The contracted waterproofer will provide a copy of the manufacturers waterproofing schedule, technical specifications, MSDS, warranty and manufacturer inspection commitment schedule for approval by Hutchies prior to commencement of works.