3.1 Access panels are to be provided adjacent all internal units sufficient to carry out scheduled maintenance including cleaning of coils, inspection of tundishes, safe-tray connections and replacement of air filters. They are all too often inadequate creating costly retrofitting needs. You do not need to provide and access hatch that allows for the replacement of the AC compressor or FCU.

3.2 Plan the location and size of access panels by coordinating the Mechanical Services Drawings with the Subcontractor’s Shop Drawings and Architectural Reflected Ceiling Plans to provide access to all required Services. Included in the planning should be the location of;

• the FCU control panel,

• multi head air-conditioning systems refrigerant gas regulation boxes

• Air Filters,

• Fire dampers,

• Motorised air supply dampers (locate these near access panels to avoid additional access panels where possible),

• Exhaust fans (such as toilet exhausts),

• Kitchen Duct drainage points and

• Fresh Air intake louvers which will require separation from exhaust vents.

3.3 Refer Ceiling and walls policy and wet areas policy for additional review of this issue

NOISE CONTROL (SOUND ATTENUATION)

3.4 Mechanically fix all units to support structure with vibration isolation mounts. Refer to an Acoustic Consultant where noise transfer specifications require.

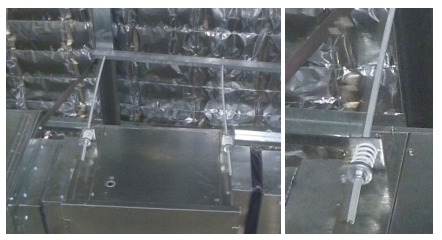

3.5 OUTDOOR UNITS

Above - Rubber Pad Vibration Damper

Above - Sprung Vibration Damper

3.6 INDOOR UNITS

3.7 EXHAUSTS

3.7.1 Check the council noise requirements set in the Development Approval and provide any mandatory acoustic and / or visual screening louvers / treatment for noise control of equipment. Have this tested and certified prior to completion via proper acoustics testing.

3.7.2 Refer also Acoustic and Fire rating policy for information on acoustic louvers.