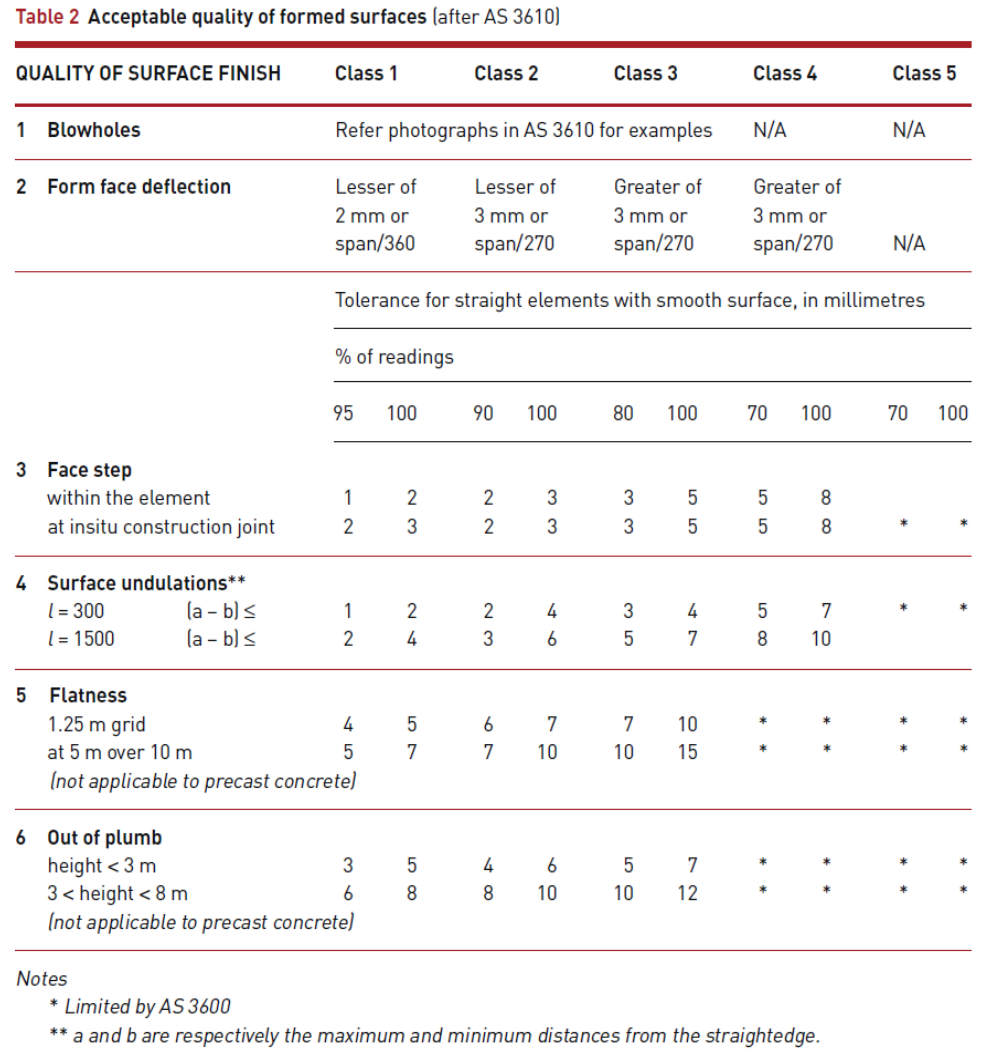

3.1 Formwork is determined by the code of practice (workplace health and safety) for design of the formwork support systems and the Australian standard 3610 which dictates the quality standards including surface finish and tolerance.

3.2 Commonly referred to as the formwork “class” with class 1 is almost unachievable high quality works (like an exposed façade); down to class 5 which is essentially low quality in ground works (like pool shell formwork).

3.3 Formwork quality is determined by 4 main issues:

3.3.1 Sufficient bracing and support of the formwork during pouring. The shape and size of formwork needs be maintained during concrete placement. The result of failure to do this is excessive deflection in concrete elements – such as concrete slabs; and blowouts in formworks – such as wall shutters that dislodge.

3.3.2 Good concrete leakage prevention – fillets (plastic do not absorb moisture like timber fillets and are therefore more suitable for off form finishes), sealing joins in sheets of ply to prevent leakage.

3.3.3 CONCRETE PLACEMENT techniques. Poor placement by the concreter or pump operator WILL result in movement of formwork such as rebates, set downs and so on. Dumping to much concrete into a single sided formwork wall will simply blow it out – and the 200mm thick wall will become 300mm at the base and 210mm at the top - very expensive to fix. Form workers can complete their works well and have all their hard work undone in just minutes by poor concrete placement – it MUST be supervised and CONTROLLED on site (not from an office).

3.3.4 Traffic – the many trades that access a deck to complete works (steel fixer, concreter, supervisors, engineers, plumbers, electricians etc) can easily step on or displace formwork. Check and recheck and - then recheck again as the works progress.

3.4 It is evident that some of the ‘formwork’ problems are simply a lack of respect for the formwork by other trades.

3.5 The main areas of regular formwork/concrete placement failure is:

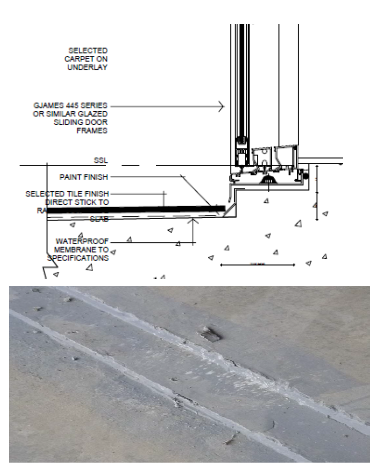

3.5.1 Rebates

a. Ensure rebates are adequate and aligned correctly and securely fixed prior to pours.

b. Maintain the integrity of rebate formwork during the pour to avoid costly re-work post pour/placement.

c. Poorly formed or inadequate rebates and set downs can cause water ingress and will increase the cost for following trades.

Above - Rubbish rebate - not acceptable.

Above - Slighly better but not acceptable.

3.5.2 Set downs

a. The bathroom area set downs are formed or knocked out of position in probably 50% of all areas on every job. This is unacceptable.

b. This can be reduced by onsite checking and supervision of the works during the concrete placement activities when they are most commonly affected – see next page of this policy as well.

Above - Rebates formed incorrectly. To be cut/jackhammered out; or extended; and made good for waterproofing.

Above - Disgraceful finish on concrete set down areas

Above - Set downs knocked during pour – 70mm out of place – unacceptable

Above - Steel edge forms for highly repetitive works save time and produce a far better set down.

3.5.3 Blowouts

a. Blowouts (failure of the form to contain the concrete – generally result from poor concrete placement and/or insufficiently braced/supported formworks

b. Despite engineering signoff being required pre-pour – this can only be assumed to prevent a failure leading to collapse. This doesn’t prevent excessive deflection or leakage etc.

c. Avoided by conducting a review of the formwork and looking at the supports subjectively to ensure adequacy. Decks are the worst areas. Read the formwork code and understand what is required.

3.5.4 Plumb

a. Facades and especially lift shafts have very strict tolerances that require survey checking floor by floor to ensure the walls are built in a plumb alignment. If not the lift will not run or run smoothly.

b. Typical lift shaft tolerances are +0/-25mm, meaning the shaft cannot be smaller, but it can be 25mm bigger. This is OVERALL top to bottom and anywhere in between. The rails on a lift car are straight from top to bottom and must be plumb. They cannot be on a lean, or going in an out to follow the walls.

c. The cost of scabbling back a 30 storey lift shaft wall or any part of it would be considerable; as would be fabricating a special lift car.

d. Facades may be off form and therefore unable to have extensive rectifications - removal of a non-complying wall during the construction process is a significant cost.

3.5.5 Class of finish – off form works

a. The requirement to achieve a specified class of finish is a project specific requirement and covered in the finishes schedule.

b. The class of finish result is typically misunderstood between client/designer/form-worker and builder.

c. Find examples of what is specified and agree on the expectation – and then complete a “middle of the range” prototype showing the support hole patching and finish, the sheet joints, fillet edges etc. This is often a hold up in obtaining the final payment or Bank Guarantee for the site.

Above -Class 2 (“low” end of the range) Result - poor quality façade

Above - Class 2 (“upper” end of the range) Result - good quality finish

d. Class of finish – soffitsA significant area of cost and issue is the surface finish on soffits of balconies and walkways where the off form concrete is to be light texture painted.

3.5.6 Class of finish – soffits

a. A significant area of cost and issue is the surface finish on soffits of balconies and walkways where the off form concrete is to be light texture painted.

Above - Stripped soffit forms

Above - Soffit to patching/grinding by formworker complete

Above - High quality resort – painter preparation included white joints to feather out concrete to provide defect free substrate

Above - Painted soffit – the lighter the texture the more visible the imperfections as a general rule