- 1 Minute to read

- Print

- PDF

3. Plumbing Works - Walls (Drainage/Water Services Penetrations)

- 1 Minute to read

- Print

- PDF

3.1 Similar to floor penetrations – penetrations in waterproofed walls in wet areas need to be sealed properly to prevent water breaching the wet area “containment” boundaries and ruining linings and leaking into adjoining areas and down to the set down where it will delaminate the membrane.

3.2 First and foremost – penetrations for taps are NOT to made by smashing a hole in the wall linings with a hammer – they are to be set out and cut out properly to ensure the penetration is a snug fit around the service

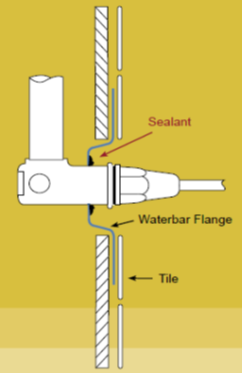

3.3 Water bar tap flanges will be installed by the plumber for all conventional tap penetrations to all wet areas in bathrooms, laundries, and kitchens

3.4 The waterproofer will install and polyurethane seal around the tap against the

waterbar flange

3.5 The flange will be waterproofed by the waterproofer when completing the walls.

3.6 NOTE - the waterproofing contractor will not commence waterproofing walls until the flanges are installed and sealed with Polyurethane sealant is installed and preparation works are complete.

3.7 Shower head penetration will be fully sealed with Polyurethane sealant finished level with the finished wall surface.

3.8 Mixer installations will be fully sealed using polyurethane sealants between the mixer cartridge and the edge of the wall sheeting level with the finished wall surface before the waterproofing is carried out. A second seal will be installed between the finished wall surface and the back of the mixer flange.

3.9 The penetration gap between the flange or cartridge and wall will not exceed 8mm or the sheet will be replaced.

3.10 Clients will be advised of cartridge servicing requirements including the requirement that both seal will need to be renewed by a licensed plumber during servicing.

3.11 Sufficient flexible pipe (braided hose) will be used from the wall to the cistern tank on the WC to create an even bend. Kinked or twisted pipe work is unacceptable and will be replaced.

3.12 All services to be isolated from metal wall framing to prevent hammering of the pipe work during tap operation.