3.1 The ABCB advisory note at the back of this document describes the differences and impact on selection.

3.2 The CSIRO reference document provides similar clarity (extracts below):

For buildings requiring Type and B construction the BCA Deemed to Satisfy provisions addresses two common cases relating to fire performance of external walls:

- The cladding is the exterior wall or part of the wall. (BCA Specification C1.1, Sections 3.1(b) & 4.1 (b) apply)

- https://ncc.abcb.gov.au/editions/2019-a1/ncc-2019-volume-one-amendment-1/section-c-fire-resistance/specification-c11-fire

- The cladding is an attachment to an exterior wall having the required FRL (BCA Specification C1.1 Clause 2.4 applies)

The term "external wall" is defined in the BCA as "... an outer wall of a building which is not a common wall". - If the cladding/lining/other item is removed and the remaining structure no longer functions suitably as a external wall (for example, the remaining structure has no fire resistance level, is unable to prevent the penetration of water, is under to resist wind loads, or in certain applications cannot meet acoustic requirements), then it is considered an integral part of the external wall, and BCA Specification C1.1, Section 3.1(b) & 4.1 (b) applies.

- If the cladding/lining/other item is removed and the remaining wall system still functions as an external wall then Sepc C1.1 Clause 2.4 applies.

3.3 Why differentiate between them?

If the cladding is an attachment (not a wall by definition to the NCC) it may not need to be a non-combustible element.

(a) A combustible materialmay be used as a finish or lining to a wall or roof, or in a sign, sunscreen or blind, awning, or other attachment to a building element which has the required FRL if -

(i) The material is exempted under C1.10 or complies with the fire hazard properties prescribed in Specification C1.10; and

(ii) it is not located near or directly above a required exit so as to make the exit unusable in a fire; and

(iii) it does not otherwise constitute an undue risk of fire spread via the facade of the building.

(b) The attachment of a facing or finish, or the installation of ducting or any other service, to a part of a building required to have an FRL must not impair the required FRL of that part."

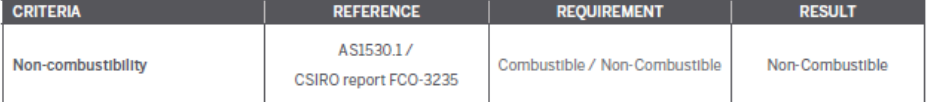

3.4 If it’s a part of the wall – in Type A & B construction, the cladding must be non-combustible. (AS 1530.1 tested.)

3.5 If it’s an attachment in Type A & B construction, it ‘may’ be permitted as combustible to the limits in Clause 2.4 (AS 1530.3 tested) and noting that exits/paths of travel should remain non-combustible.

3.6 Regardless of the NCC having no requirement for non-combustible materials, Type C should be at a minimum, limited combustibility to the values in Clause 2.4 (AS 1530.3 tested) and using a non-combustible product is the best outcome to reduce risk.

3.7 For simplicity HB are progressing with ALL claddings to TYPE A & B construction as non-combustible regardless of being a wall or an attachment unless there is clear FER/Certifier/authority approval for an alternative solution and this is signed off by The Quality Team and the Team Leader.

3.8 All TYPE C buildings should use a non-combustible 1530.1 cladding to exits and are subject to The Quality Team and Team Leader approval. Use non-combustible (preferred) or fire resistant (FR/A2) ACP products and Kingspan or equal wall PIR panels with AS 1530.3 testing to other areas.

3.9 In Type A and B there is a requirement for the external walls to be ‘non-combustible’, whereas in Type C there is no requirement for non-combustible materials:

TYPE A FIRE - RESISTING CONSTRUCTION

Fire-resistance of building elements.

In a building required to be of Type A construction -

(a) each buiding element listed in Table 3 and any beam or column incorporated in it, must have an FRL not less than that listed in the Table for a particiular Class of building concerned; and

(b) external walls, common walls and the flooring and floor framing of lift pits must be non-combustible; and

TYPE B FIRE-RESISTING CONSTRUCTION

Fire-resistance of building elements

In a building required to be Type B construction -

(a) each building element listed in Table 4, and any beam or column incorporated in it, must have an FRL not less than that listed in the Table for the particular Class of building concerned; and

(b) the external walls, common walls, and hte flooring and floor framing in any lift pit, must be non-combustible; and"

3.10 As there are a lot of Type A and B buildings constructed by HB - we have a lot of requirements for non-combustible external walls as DTS or alternative solutions as the case may be.

3.11 In respect to Type C construction, consideration to the client requirements (fit for purpose/contractual obligations) may exceed NCC compliance. Ie: a client may require a non-combustible cladding regardless of the NCC permitting a combustible cladding.

5.1 Fire-resistance of building elements

In a building required to be of Type C construction-

(a) a building element listed in Table 5 and any beam or column incorporated in it, must have an FRL not less than that listed in Table for the particular Class of building concerned; and

(b) an external wall that is required by Table 5 to have an FRL need only be tested from the outside to satisfy the requirement; and"

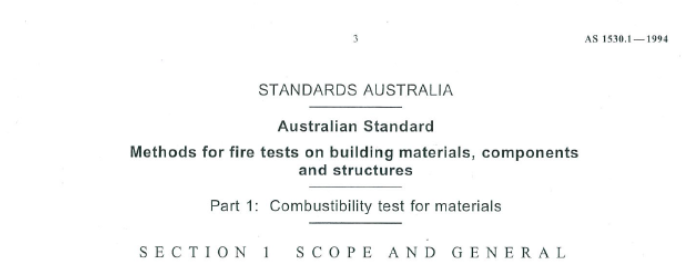

3.12 The NCC definition for non-combustible is referenced in the definitions section which requires all materials to be tested in accordance with AS 1530.1 for combustibility.

Non-combustible means -

(a) applied to a material - not deemed combustible as determined by AS 1530.1 - Combustibility Test for Materials; and

(b) applied to construction or part of a building - constructed wholly of materials that are not deemed combustible.

Testing to AS 1530.1

3.13 Particularly relevant to ACP/ALP is C1.12:

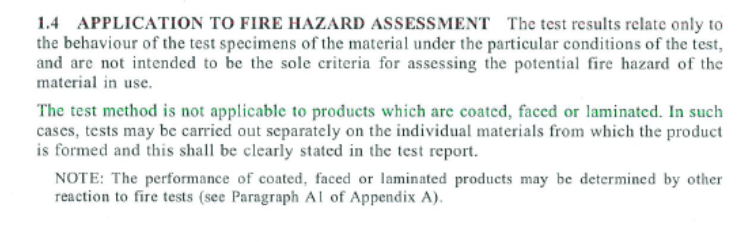

3.13.1 AS1530.1 states it’s not suitable for laminated products:

So under C1.12, the NCC provides an exemption to recognise certain ‘Bonded Laminated Panels’ as non-combustible – meaning it can be tested as the non-glue components only – ie the aluminium facing panels and the aluminium core.

The following materials, though combustible or containing combustible fibres, may be used wherever a non-combustible material is required:

(a) Plasterboard.

(b) Perforated gypsum lath with a normal paper finish.

(c) Fibrous-plaster sheet.

(d) Fibre-reinforced cement sheeting.

(e) Pre-finished matal sheeting having a combustible surface finish not exceeding 1mm thickness and where the Spread-of-Flame Index of the product is not greater than 0.

(f) Bonded laminated materials where -

(i) each laminated non-combustable; and

(ii) each adhesive layer does not exceed 1mm in thickness; and

(iii) the total thickness of the adhesive layers does not exceed 2 mm; and

(iv) the Spread-of-Flame Index and the Smoke-Developed Index of the laminated material as a whole does not exceed 0 and 3 respectively."

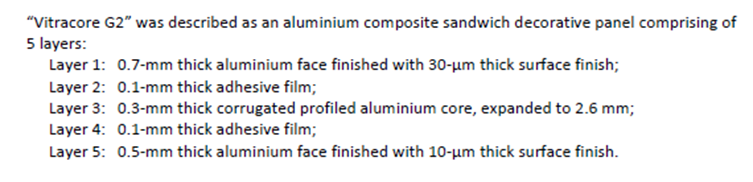

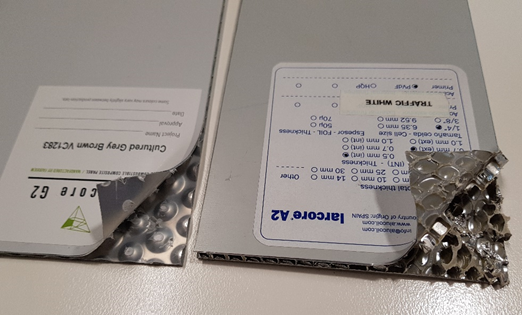

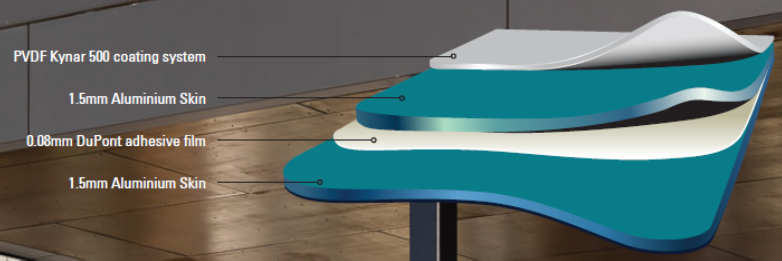

3.13.2 Essentially as long as there are no more than 1mm individual layers of glue and no more than 2mm total thickness of glue (ie 2 layers of 1mm max thickness glue) - which is essentially honeycomb type ACP panels and ALP, the NCC permits these forms of panels to be tested without the glue - and of course they pass and are deemed ‘non-combustible’.

3.13.3 This section also nominates a few materials that are deemed non-combustible elements like fibre cement (ie doesn’t need to be tested to AS1530.1 as it’s deemed acceptable).

3.14 The NCC also recognises a few things that are technically combustible but provides an exemption – like paint on a fibre cement panel for example – the paint is exempt - refer C1.10(c) for the list of items:

(a) The fire hazard properties of the following linings, materials and assemblies in a Class 2 of 9 building must comply with Specification C1.10:

(c) The requirements of (a) do not apply to a material or assembly if it is -

(i) plaster, cement render, concrete, terrazzo, ceramic tile or the like; or

(ii) a fire-protective covering; or

(iii) a timber-framed window; or

(iv) a solid timber handrail or skirting; or

(v) a timber-faced solid-core door or timber-faced fire door; or

(vi) an electrical switch, socket outlet, cover plate or the like; or

(vii) a material used for -

(A) a roof insulation material applied in continuous contact wtih a substrate; or

(B) an adhesive; or

(C) a damp-proof course, flashing, caulking, sealing, ground moisture barrier, or the like; or

(viii) a paint, varnish, lacquer or similar finish, other than nitro-cellulose lacquer; or

(ix) a clear or translucent roof light of glass fibre-reinforced polyester if -

(A) the roof in which it is installed forms part of a single storey building required to be Type C construction; and

(B) the material is used as part of the roof covering; and

(C) it is not closer than 1.5m from another roof lift of the same type; and

(D) each roof light is not more than 14m2 in area; and

(E) the area of the rof light per 70m2 of roof surface is not more than 14m2, or

(x) a face plate or neck adaptor of supply and return air outlets of an air handling system

or

3.15 Products that have been tested to meet the AS 1530.1 non-combustible cladding definition are:

3.15.1 the honeycomb core type panels Vitracore G2, Larson A2, Bluechip Ultracore G2. Note: this is PRE NCC 2019 bonded laminate changes which removes the exemption for these products to allow AS1530.1 compliance so HB policy to adopt now – these products are not to be used without special approval by Quality team and an FER

3.15.2 ALP – Aluminium Laminated Panels – such as Reynodual – which comprise 2 pieces of aluminium glued together as a laminated panel - ie these do not have a honeycomb type core. Note: this is PRE NCC 2019 bonded laminate changes which removes the exemption for these products to allow AS1530.1 compliance so HB policy to adopt now – these products are not to be used without special approval by Quality team and an FER.

3.16 ASP – Aluminium Solid Panels such as Vitradual and other solid panels such as zinc and copper.

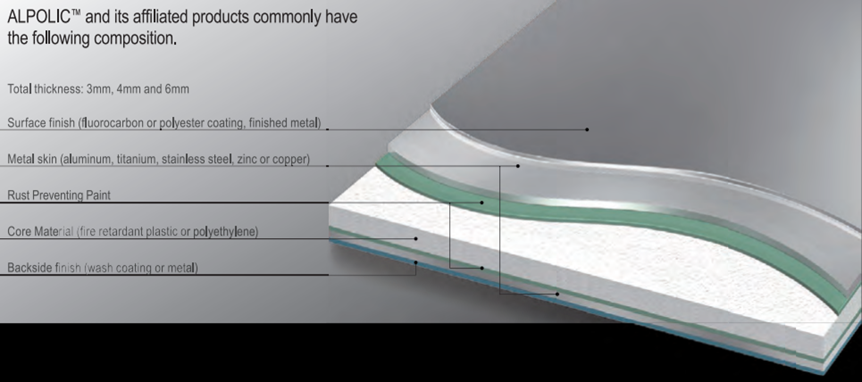

3.17 Products that are not AS 1530.1 tested include Alpolic FR (Fire Resistant core), Alpolic A2, Alucobond A2, Vitrabond, Kingspan PIR panels, Bondor EPS panels, Modwood, Solid timber etc.

3.18 These products have an adhesive/core that is thicker than permitted by NCC C1.12, meaning they are not exempt like the honeycomb panels and cannot be tested to AS 1530.1 as non-combustible. So instead they are tested to AS 1530.3 – methods for testing ignitability, flame propagation, heat release and smoke release.

3.19 Modified timber and natural timber products require a separate performance assessment based on detailed testing for char factors etc and requires specialist engineering.

3.20 They may be very limited combustibility and suitable/safe for use – but they are not ‘non-combustible’ by definition so cannot be used as a ‘DTS’ solution.

3.21 To be clear – ‘PE’ Core cladding materials are NOT permitted to be used on HB projects ‘FR’ Mineral Core may be used where approved correctly

3.22 The only way to use one of these products in TYPE A or B construction is using the performance assessment part of the NCC (Part A section A2.2).

3.23 To do this, a suitably qualified fire engineer/certifier/building surveyor determine that the use of a product is suitable (despite not being AS 1530.1 tested) – which needs to be documented as an assessment by the certifier/building surveyor using assessment methods of the NCC A0.5 which includes: (see Performance Assessment Flowchart at rear of this document)

A0.5 Assessment Methods

The following Assessment Methods, or any combination of them, can be used to determine that a Performance Solution or a Deemed-to-Satisfy Solution complies with the Performance Requirements, as appropriate:

(a) Evidence to support that the use of a material or product, form of construction or design meets a Performance Requirement or a Deemed-to-Satisfy Provision as described in A2.2

(b) Verification Metholds such as -

(i) the Verification Metholds in the NCC; or

(ii) such other Verification Methods as the appropriate authority accepts for determining compliance with the Performance Requirements

(c) Expert Judgement

(d) Comparison with the Deemed-to-Satisfy Provisions

3.24 With reference A0.5 (a) and the A2.2 Evidence of suitability assessment, the provision of CodeMark certificates which confirm the product’s use is acceptable in certain circumstances (it’s important to read exactly what the certificate permits though) – so everyone can rely on it rather than everyone having to do their own special assessment for conformity to the NCC every time they want to use a product.

3.25 Noting there are published limitations on the products covered by the CodeMark certificate – which means a Fire engineers really needs to review these.

3.26 A0.5 (d) Expert judgement by documenting the solution in an FER (Fire Engineering Report) - usually by an experienced and qualified fire engineer.

3.27 Note that there are restrictions to the use of combustible products at specific areas like fire exits (eg fire exit doors and associated pathways, carpark egress etc) per Specification C1.1 Clause 2.4 (usually fire engineers/certifiers/building surveyors deem this to be within 3m of the exit door in the external wall).

(a) A combustible material may be used as a finish or lining to a wall or roof, or in a sign, sunscreen or blind, awning, or other attachment to a building element which has the required FRL if -

(i) the material is exempted under C1.10 or complies with the fire hazard properties prescribed in Specification C1.10; and

(ii) it is not located near or directly above a required exit so as to make the exit unusable in a fire; and

(iii) it does not otherwise constitute an undue risk of fire spread via the facade of the building.

(b) The attachmnet of a facing or finish, or the installation of ducting or any other service, to a part of a building required to have FRL must not impair the required FRL of that part.

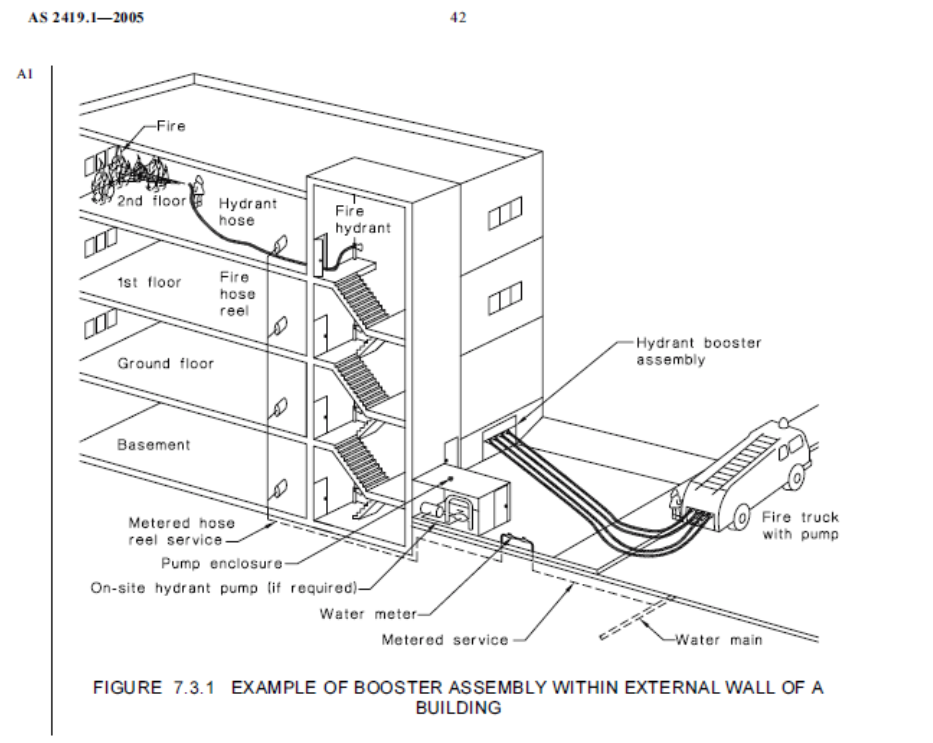

And special fire services like Hydrant boosters (refer AS 2419) – so in any performance solution the FER needs to confirm what’s required in these locations to meet CP2 (a)(i).

7.3 LOCATION

Fire brigade booster assemblies shall be located so that they meet the following requirements:

a) They are readily accessible to firefighters.

b) They are operable by fire brigade pumping appliances located within 8m.

c) If within, or affixed to, the external wall of the building, the booster shall be-

i) within sight of the main entrance of the building; and

ii) separated from the building by a constrcution with a fire resistance rating of not less than FRL 90/90/90 for a distance of not less than 2m each side of and 3m above the upper hose connections in the booster assembly.

NOTE: an example of a booster assembly within the external wall of a building is shown in Fgure 7.3.1.

3.28 Whether a DTS or performance solution is used, there are also considerations that apply including the integration of the cladding to the remainder of the wall system.

3.29 Specification C1.1 outlines the requirements for fire resisting construction. Table 3 for Type A, Table 4 for Type B & Table 5 for Type C. Each building element listed in the tables, must have an FRL (Fire Resistance Level) not less than that listed in the Table for the particular Class of building concerned. A tested system must be used to achieve the required FRL.

3.30 If the building has an FRL, and the cladding is connected to the FRL wall, it is not permitted to impact on the FRL - so particularly for lightweight tested systems (eg plasterboard, shaft wall etc), the wall system must be tested to permit the connection or a fire engineer must provide advice on the performance of the system in the proposed design to confirm the FRL is not impaired. This needs to be noted in the FER/in an Engineering assessment report.

Eg if a tested 2 hour plasterboard wall is used on the external of a building with a Vitracore GR DTS compliant cladding or a Alpolic FR combustible non DTS cladding – evidence would be required from the wall designer that the battening required for the Cladding doesn’t impact on the fire rating of the wall.

Typically, attachments to the wall which are supported by the wall would make the wall loadbearing and this would impact the FRL required for the wall.

In all cases the attachment must not impair the FRL of the wall. Attachments could possibly impair the FRL of the wall in the following ways;

- Any fixings or penetrations into the wall to support the attachment may influence the integrity or insulation of the wall syste.

- Any significant force loads beyond that of the originally fire tested wall system may influence the structural adequacy or integrity of the wall system.

- Significant increased heat release near the surface of the wall may influence the structural adequacy, integrity or insulation of the wall system.

It is recommended that any impairment of FRL should be determined by AS1530.4 testing by a Registered Testing Authoirty or, where reasonable, assessment by a suitably qualified and experienced person.

The CodeMark certificates limitation directly relates to this – they cannot certify the cladding will perform in each wall type without specialised fire engineering review.

3.31 All products considered for use must have the test reports/certificates/fire engineering reports available prior to use. They must be independent NATA approved testing companies that provide these test reports (Exova, CSIRO, Branz).

Ensure the report is valid and consider any ‘disclaimers’ or right to withdraw such as below where the document is an opinion of a product untested to a recognised AS (ie uses international testing + fire engineers’ opinion to justify compliance in lieu of actually testing the product properly).

This assessment report will lapse on 30 November 2020. Should you wish us to re-examine this report with a view to the possible extension of its term of validity, would you please apply to us three to four months before the date of expiry. This Division reserves the right at any time to amend or withdraw this assessment in the light of new knowledge.

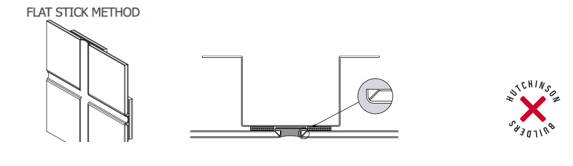

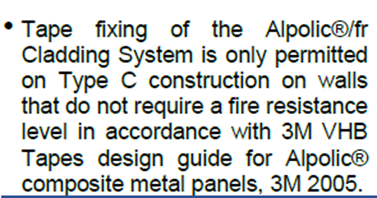

3.32 It’s important to note that ACP/ALP products can be fixed in place in a number of ways – mechanically fixed (screwed in place) or adhesive fixed (VHB –very high bond adhesive tape).

3.32.1 In TYPE A and B construction the products are required to be mechanically fixed – called ‘Fixed Cassette’.

3.32.2 Adhesive fixed only does not perform in fire, whereas mechanically fixed is screwed in place which prevents the panel falling off in a fire.

DON’T use this method unless Team Leader/The Quality Team approved.

3.32.3 Refer to the CodeMark certificate for details of each product installation requirements as tested/verified/certified – extract from copy of CodeMark Certificate below:

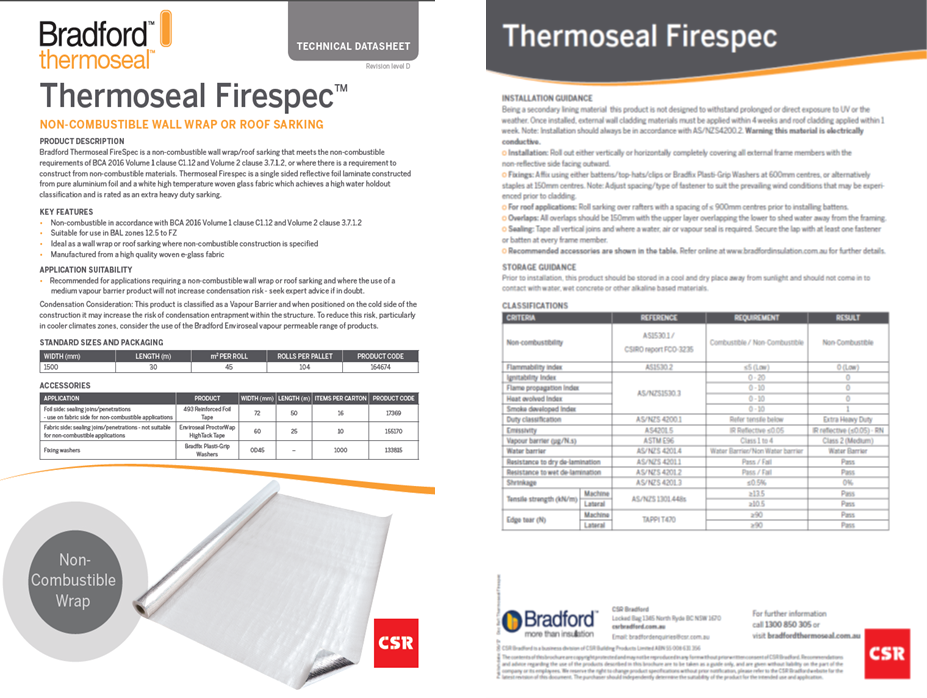

3.33 In respect to the use of sarking and insulation behind the cladding – this is required to be:

• TYPE A & B per C1.1 3.1(b) and 4.1(b) - the sarking/insulation cannot be less than the wall cladding itself which is non-combustible so the** sarking must be non-combustible tested to AS 1530.1 – unless its approved under a performance assessment to be AS1530.2 tested by the Fire engineer (via the FER) and building certifier/surveyor + authorities as required.**

• TYPE C construction must meet the requirements of Specification C1.10 (a) (vii), and (ix) and tested to AS1530.2 for sarking and AS1530.3 for insulation.

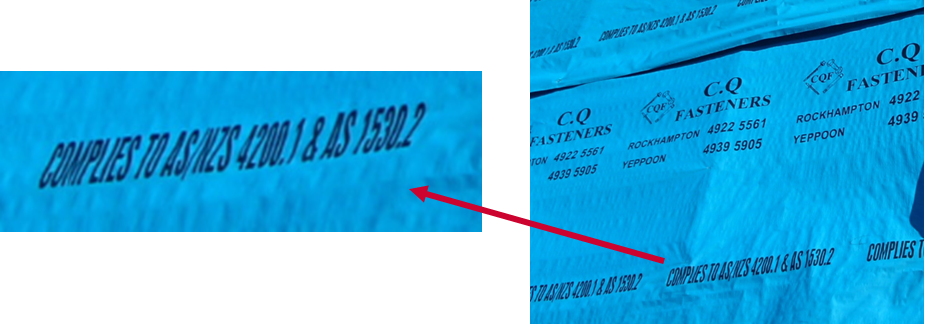

• Make sure you inspect the products supplied to site and identify what is being used – they should be marked as below.

C110 Fire hazard properties

a) The fire hazard properties of the following linings, materials and assemblies in Class 2 to 9 building must comply with Specification C1.10:

i) Floor linings and floor coverings.

ii) Wall linings and ceiling linings

iii) Air-handling ductwork

iv) Lift cars

NSW C1.10(a)(v)

v) In Class 9b buildings used as a theatre, public hall or the like -

A) fixed seating in the audience area or auditorium; and

B) a proscenium curtain required by Specification H1.3.

vi) Escalators, moving walkways and non-required non fire-isolated stairways or pedestrian ramps subject to Specification D1.12

vii) Sarking-type materials

viii) Attachment to floors, ceilings, internal walls and the internal linings of external walls.

ix) Other materials including insulation materials other than sarking-type materials.

Flammability Index means the index number as determined by AS 1530.2

Fire hazard properties means the following properties of a material or assembly that indicate how they behave under specific fire test conditions:

a) Average specific extinction area, critical radiant flux and Flammability Index, determined as defined in A1.1.

b) Smoke-Development Index, smoke development rate and Spread-of-Flame Index, determined in accordance with Specification A2.4.

c) Group number and smoke growth rate index (SMOGRArc), determined in accordance with Specification C1.10.

1. Scope

This Specification sets out requirements in relation to the fire hazard properties of linings, materials and assemblies in Class 2 to 9 buildings as set out in Table 1

Smoke-Developed Index means the index number for smoke determined by AS/NZS 1530.3

Sarking-type material means a material such as a reflective insulation

or other flexible membrane of a type normally used for a purpose such as water proofing, vapour proofing or thermal reflectance.

Reflective insulation means a building membrane wiht a reflective surface such as a reflective foil laminate, reflective barrier, foil batt or the like capable of reducing radiant heat flow.

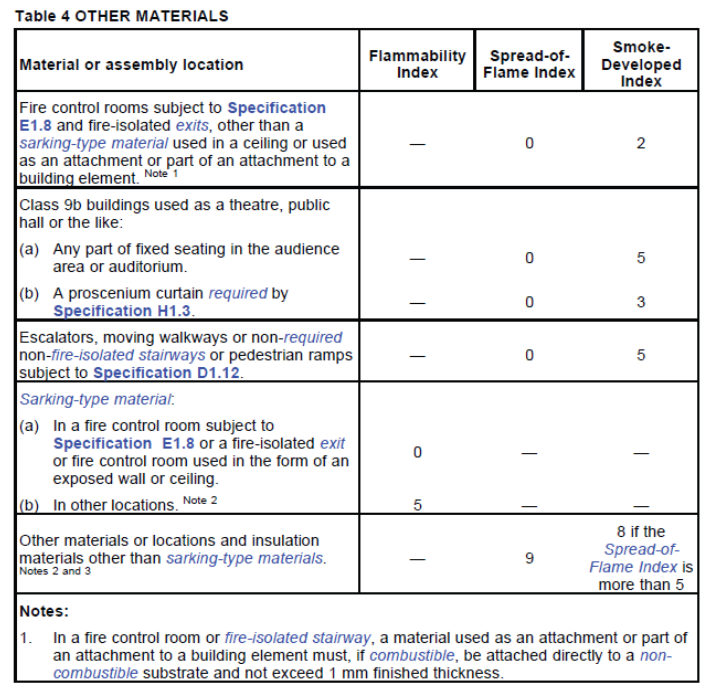

7 Other materials

NSW Spec C1.10 NSW 7

Materials and assemblies in a Class 2 to 9 building not included in Clauses 3, 4, 5 or 6 must not exceed the indices set out in Table 4.

3.34 Any of these performance solutions (non-DTS solution) may also trigger an approval by the fire brigade in many cases as well (as they need to ensure anything that may affect their ability to fight a fire and as per section CP9 of the NCC) – depending on state based legislation (your building certifier/surveyor can advise.

Specifically - any alternative solution that impacts on the performance of the building for spread of fire is usually reviewed by and approved by the fire brigade.

NATIONAL – NCC references Fire brigade related interests in buildings and provides several definitions (that are used by other State based legislation – eg fire safety systems)

CP9

Access must be provided to and around a building, to the degree necessary, for fire brigade vehicles and personnel to facilitate fire brigade intervention appropriate to -

a) the function or use of the building; and

b) the fire load; and

c) the potential fire intensity; and

d) the fire hazard; and

e) any active fire safety system installed in the building; and

f) the size of any fire compartment.

Queensland

Part of the QLD Building Act and regulations as legislated controls for building work and reference the need for ‘referral agencies’ to be involved in building design approvals and inspections to ensure the works are safe.

http://www.hpw.qld.gov.au/SiteCollectionDocuments/SpecialFireServicesGuidelines.pdf

Victoria

Part of the Victorian Planning Act and regulations.

http://www.mfb.vic.gov.au/media/docs/Guideline_33_Performance%20Based%20DesignWithinTheBuiltEnviromentV2-f000d8de-6eb2-4989-9a2e-f4c10aea1117-0.pdf

New South Wales

Part of the NSW Planning Act and regulations.

http://www.fire.nsw.gov.au/page.php?id=9149

3.35 Ultimately the Certifier’s final occupancy certificate/certificate of classification needs to state the performance solutions (referred to as an alternative solution – see section 7 of a Form 11 for QLD – other states have similar requirements).