- 1 Minute to read

- Print

- PDF

4. Slip Resistance

- 1 Minute to read

- Print

- PDF

Slip resistance requirements are generally outlined in the Australian standards GUIDELINE document HB197.

4.1 All stair treads will contain a non-slip tread (R10) and/or 25 mm non-slip nosing (R11) including landings to the outer edge (refer stair matrix for requirements). This applies to all stairs including polished timber. Non slip finishes are to be job specific and will be of the following materials unless otherwise approved by the Quality Manager. The non-slip finish needs only be on the outer edge of the tread/going.

Construction Methods to Achieve Non-Slip

• Broom finished concrete with contrasting paint finish nosing.

(Over time wear will cause a smoothing of broom finished coarseness making a non-compliance risk)

• Non slip paints.

• Carborundum abrasives broadcast into the surface of the finish.

• Grooved edge tiles.

• Slip resistance self-adhesive taps.

• Aluminium/rubber treads or nosing.

• Other methods approved by the Quality Manager.

4.2 NB – This also applies to ramps and designated pedestrian access ways external or areas subject to wetting.

4.3 Non slip finishes will contain a 30% contrasting colour to the tread in accordance with section 9.1C of AS1428.1. If this standard applies to the stairways then contrast is required. I.e.: stair to access platform will not need contrasting colour; however a fire stair used for general public use will require a contrast colour. Contrast must be used where the vision impaired could have access to the area.

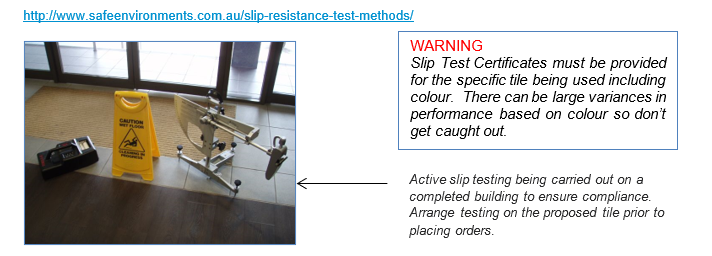

4.4 Slip testing will be carried out on nominated public areas in commercial and industrial areas and certified on completion of shopping centres, hotels, residential complexes and building where reasonable public access is available.

4.5 Ensure we provide a non-slip maintenance schedule on non-slip treads/surfaces at the time of handover within the Maintenance Manual stating method and frequency of cleaning and re-application of products as required by the Manufacturer. This is essential in dissolving our on-going risk and defects due to a lack of owner maintenance.