There are hundreds of different of baths but they are all installed in one of the following ways;

6.1 Free standing baths

6.1.1 Fairly self-explanatory – tiles and waterproofing extend under the bath.

6.1.2 A free standing bath (or any vessel) less than 150mm from a wall is considered to be fixed to the wall and appropriate waterproofing of the wall must be carried out.

6.1.3 Seal around perimeter of the bath base.

6.2 Hob mounted (called “shelf” mounted in AS3740) baths

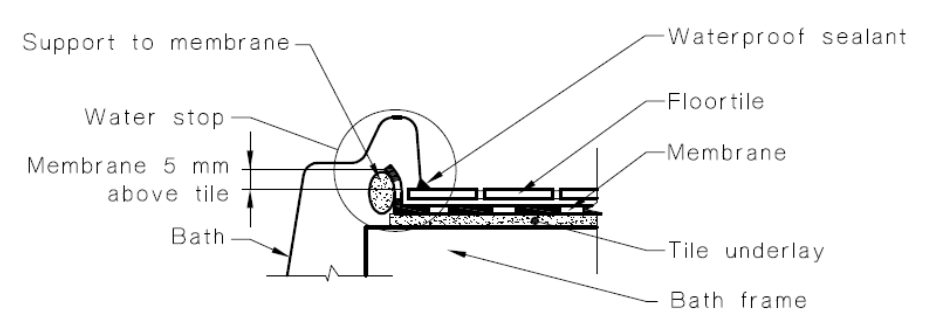

6.2.1 Provide an angle around the rim of the bath and membrane to the angle over the entire bath frame to prevent “shelf” or “hob” surface water tracking back under the bath rim into the void under the bath

6.3 Built in to the wall (recessed) baths

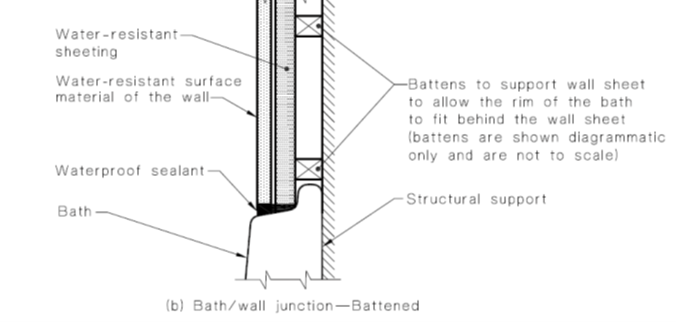

6.3.1 Baths that are recessed into walls are moulded with a “lip” to the edge.

6.3.2 The wall linings are brought down over the lip and the junction sealed.

Above - Recess detail

Above - Bath with moulded ‘lip’

6.4 Partially hob/partially built in:

6.4.1 It’s important to get a bath that is setup to be built into the wall. This can either be a bath that is designed standard to be built in, or it may require using a hob designed bath with a FACTORY fitted wall installation “lip” – see photo left

6.4.2 Without the wall “lip”, the bath cannot be built into the wall, will not be in compliance with AS 3740 and WILL leak.

Above - hob bath provided with a factory lip built into the wall.

Above – factory lip on a hob bath at the back/left side, hob bath at the front/right side.

6.5 Spa Baths

6.5.1 May be either hob, free standing or built in bath

6.5.2 May have motor under the bath (typical) or remotely located

6.5.3 The pipework UNDER the bath that serves the spa jets may leak, and as result the bath frame is sheeted to 150mm high and the base of the UNDERSIDE of the bath is waterproofed. In good installations the area is provided with a floor waste to drain the water in the event of a leak

6.5.4 The spa motor is located on a plinth (out of any potential water in the base) and as per the manufacturers requirements. The ordering of a spa requires the nomination of a motor location – it’s important to get this right!!! – Every bath install is different.

6.5.5 To service the floor waste, detect leaks and the motor, an access panel – typically 400 x 500mm is required – large enough to remove the spa motor. This is more often than not in a tiled face and consideration to the access panel construction is covered further in this policy

6.5.6 Finally – spa baths can be supplied with a support frame (as opposed to having to be the bath) considering the pipework and risk of damage to pipes in the bedding process – it is a sensible way to have the bath supplied.

6.5.7 See also photos of the “hob” bath - which is a hob spa bath – showing the waterproofing under the bath.

Above - Spa bath on factory support frame