- 7 Minutes to read

- Print

- PDF

7. General

- 7 Minutes to read

- Print

- PDF

7.1 If we can guarantee opening sizes up front significant time savings can be achieved by reducing the need to site measure. Frames can be fabricated in standard sizes which is a significant cost saving in the manufacture and fabrication of window and door units. Aluminium Billets are cast and extruded in standard lengths to suit standard sizes. Order a nonstandard door or window and the cost increases substantially.

7.2 Reworking of opening sizes, rebates, set downs, slabs - whether within structural elements or finishing is costly but easily preventable.

7.3 Achieve this through close supervision of the works, ensuring competent people are carrying out the works then checking dimensional tolerances as the elements are being constructed. Good quality saves money.

7.4 Early discovery can also mitigate the cost of re-work and prevent any programming implications whereby materials cannot be installed due to incorrect openings that need re-work.

at the sharp edge. This is typical of any liquid material applicatio.

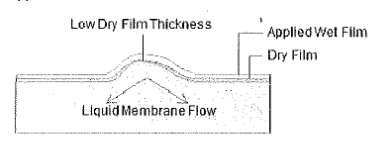

Figure 2 - Membrane applied over localized deformation

For the same reasons, when a membrane is applied over a localized deformation, be it intrusions or protrusion, the liquid material will tend to flow from the high points during the drying process leaving a film wiht a lower dry film thickness at the peak of the deformation.

Surface Accessibility

Surfaces to which a liquid membrane is to be applied must be easily accessible to a roller or brush application. This may appear to be an obvious criterion however it is frequently overlooked in the surface preparation.

In the case of off-form concrete the resulting surface frequently has numerous voids commonly called blow holes. These can either be visible voids or voids hidden under a thin cementitious skin which is a very weak and unsuitable for a membrane application.

Apart from the fact that these blow holes normally exhibit sharp edges as described above, they also frequently result in inaccessible surfaces with the void.

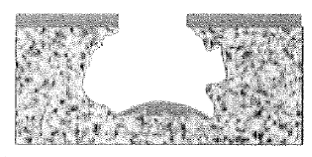

Figure 3 - Membrane applied over blow hole

Figure 3 represents the result when a membrane is applied to the surface is that there are significant surfaces within the void that are totally uncoated. This is unavoidable when the interior of the void is not accessible.

Surface Requirements of Membrane Application.

In summary therefore, the surface requirements suitable for a membrane application are:-

a. Structurally sound

b. Free of dust and other contaminants

c. Porous

d. Free from localized surface defects such as protrusions and intrusions

While the first two or even 3 of these requirements are considered the waterproofing contractors responsibility, the fourth is frequently considered by the waterproofing contractor as being part of the builder's responsibility to provide a suitable surface.

Concrete Finish in Architectural Building

As outlined previously a building specification normally calls up a concrete finish in accordance with Class 2 of AS3610 for an architectural building.

AS3610 is principally concerned with the broadspan surface finish as far as smoothness and levels and less concerned about the localised defects for which it allows a certain tolerance.

AS3610 Class 2 therefore allows a certain density of blow holes. Blowholes present a major problem for a successful membrane application as described above so the surface needs to be totally free from these defects for the surface to be suitable for a membrane application.

AS3610 Class 2 also allows for a surface deviation over extended lengths. While the extent of these deviations spread over the extended length presents no problem for a successful membrane application, when the extent of the deviation is limited to an isolated area it does become a problem. A fine scrabbled surface may conform to AS3610 but is unsuitable for a membrane application due the numerous preaks within a small localized area.

Responsibilities

Standard construction procedure is to specify the concrete finish required in accordance with AS3610.

Waterproofing requirements for concrete finish may exceed the requirements of AS3610.

Adjustments to the concrete surface profile may occur after pouring, such as adjustments to set down areas, resulting in damaged surfaces.

Damage to and contamination of the concrete surface can occur between the Concreting Contractor handover and the waterproofing contractor commencing work.

The following responsibilities are therefore proposed to avoid conflict and unexpected costs being incurred by any party.

Introduction

During the installatio of a waterpoof membrane, particular liquid membranes, there is frequently conjecture between the Concreting Contractor and the waterproofing contractor in the assessment of the surface finish.

The simple reason for this is that Builders normally specify the concrete finishes required on a project in accordance with AS3610. For an architectural project where membranes are installed the normally expected standard is Class 2 which is designated to define the limits of flatness and smoothness.

The Concreting Contractor finishes his work to this standard however complying with the requirements of this standard does not necessarily produce a surface that is suitable for a membrane application.

The waterproofing contractor tenders the installation of the membrane on the basis that the surface provided is fit for a membrane application and conflict arises.

The purpose of this Bulletin is to define the requirements for a surface finish suitable for a liquid membrane application and to outline the common differences that can exist between AS3610 Class 2 surface finish and a fuinish suitable for a membrane application.

Liquid Membrane Application

The primary requirements of an effective liquid membrane application involve achieving good adhesion to the substrate and the application of a uniform minimum dry film thickness over the entire surface to be waterproofed.

To achieve this there are a number of minimum requirements of the substrate surface in addition to it being sufficienty structurally sound to support the membrane application.

Surface Cleanliness

The substrate surface must be clean and free from lose praticles (dust and dirt) and all surface contaminants that may hinder the achievement of good bonding characteristics.

This requirement not only refers to the dirt and dust tracked in from adjacent areas but also refers to the micro-surface finish of the concrete that may be loosely bound due to the finishing process of the concrete. As an example, if the finishing of the concrete is carried out with excessive bleed water remaining, the cement fines are drawn to the surface and create a weakly bound micro-surface on the concrete.

Surface Porosity

A liquid waterpoof membrane is designed to achieve a mechanical bond by penetrating the micro-surface of the substrate and keying firmly to the concrete. To achieve this, the surface must obviously be open pored (porous) to allow the required penetration into the concrete.

Highly polished or overworked concrete are not surfaces that are suitable for a membrane application.

Care should also be taken with grinding that can turn a porous surface into a low permeability surface by pressure fine particles into the existing pores of the concrete.

Surface Finish

Liquid membranes are applied as combination of solid film forming material combined with a carrier solvent (frequently water). After application the film possesses some degree of self-leveling or self-smoothing properties as the carrier solvent evaporates leaving the dry film.

It is therefore essential, to achieve a uniform dry film thickness, that the surface finish be relatively smooth and free from sharp edges or significant protrusions or intrusions.

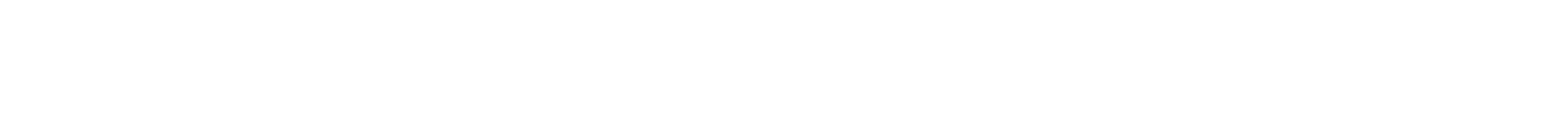

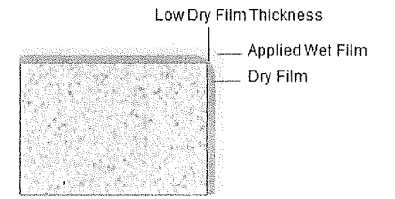

Figure 1 - Membrane applied over sharp edge.

When applied to a sharp edge (Figure 1), a liquid membrane will tend to flow away from the edge as it dries resulting in a low dry film thickness being achieved.

Builder Responsibility

- Builder is responsible for nominating the standard of surface finish required from the Concreting Contractor.

- Builder is responsible for nominating a standard of surface finish to be supplied to the waterpoofing contractor at the time of tender.

- Builder responsible for providing a surface finish in accordance with AS3510 to the waterproofing contractor.

This means the builder is responsible for the cost of remediating and damage resulting from other trades that occurs between the Concreting Contractors hand over and the builder's handover to the waterproofing contractor restoring the surface to a standard conforming to the Class of surface nominated under AS3610.

Remediation includes the removal of surface contaminants such as render deposits or other spills and the remediation of surface damage such as step breakouts or sueface impact damage.

Concreting Contractor Responsibility - The Concreting Contractor is responsible for handing over a surface finish in accordance with the specified Class under AS3610 to the Builder.

This includes the remediation of any changes to the surface after pouring such as set down area adjustments to confirm to specified Class under AS3610.

Waterpoofing Contractor Responsibility - The Waterproofing Contractor is responsible for all surface remediation necessary to upgrade the surface finish from the specified finish in accordance with AS3610.

The waterpoofing contractor should therefore allow is tendering:

- for filling surface defects such as blowholes to the extent permitted the under the relevant class of AS3610.

- For beveling or round sharp corners such as steps for set down edges.

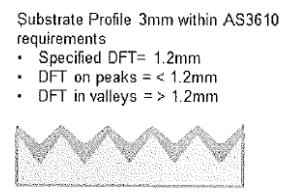

- for either smoothing or applying additional membrane over short distance surface profile deformations allowable under the relevant class of AS3610 to achieve the required dry film thickness over the peaks. (Ref Figure 4).

Figure 4 - Effects of the application of a liquid coating over surface profile peaks.

While the above defines where responsibilities lie in the process of achieving a suitable surface finish to the concrete, it does not obviate disputes regarding the assessment of surface in relation to AS3610. This can only be resolved by the appointment of a mediator to which all parties agree to abide.