7.1 Solid core doors needs to have sound door frame connections. Make sure steel stud frames have timber inserts at the hinge side to strengthen the frame and that minimum three hinges are used.

7.2 Detailed manufacturers shop drawings MUST be provided for all windows and doors installations – and MUST be thoroughly checked prior to ordering and the commencement of works.

7.3 Window flashings will be sealed using an unbroken and continual seal between the back of the flashing and the face of the window.

7.4 Windows flashings will be installed consistent with manufacturer’s details which must be held on site and provided to relevant tradespersons and our staff.

7.5 Window and door coatings used within 1000m of salt water will contain additional thickness consistent with manufacturer’s specifications for corrosive environments. See AS2047 appendix E

7.6 All powder coated surfaces and all products used within 1000m of salt water will be pre-treated with a Chromatic Primer. Powder coatings thickness will be a minimum or 60Microns and will be coated with Commercial Grade Powder. Standard grade powder will not be used within 1000m of salt water. Powder coated horizontal surfaces such as the tops of aluminium components which are more exposed must contain a minimum thickness of 70Microns within 1000m of salt water. I.e.: Tops of aluminium tack-ons and the like. See AS2047 appendix E and AS 3715

7.7 Anodised coatings must contain a minimum of a 20 Micron Thickness. Anodised horizontal surfaces with in 1000m of salt water must contain a minimum thickness of 25 Microns. See AS2047 appendix E

7.8 Ensure that flashings are PREFORMED prior to powder coating or anodising. The process of bending the flashing AFTER the finishing treatment is unacceptable and results in “crazing” and in extreme cases “whitening” of the corner where the finish is “stretched” by the bending. This weakens the corner and leaves unfinished aluminium exposed. There is no clear standard against this, but it is our policy NOT to allow this to occur. It is USUALLY adopted when flashings are lost or measured incorrectly – in other words poor management! Not acceptable

7.9 Aluminium sliding door jambs must be mechanically fixed to a solid structural member - and packed at door lock, keeper height and all fixing points.

7.10 External timber doors will be fully sealed on all faces and edges after lock and hinge notching prior to installation.

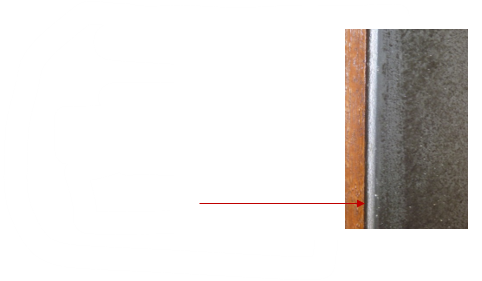

7.11 Steel door frames will be primed and rust treated on any welds or cuts prior to painting. Steel door frames will only be painted with a rust resistant paint system. Touch up of any damage to paint system must occur during construction.

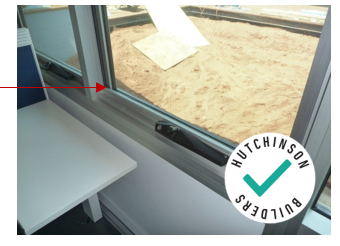

It has been found in corrosive environment that salt deposits are blown into this junction and condensation forms at the same point between air conditioned apartments and the humid outside air. The issue has successfully been avoided by installing inexpensive batwing seals in this junction.

Above - This frame has early rust around hingle points due to poor priming or damage to primed surfaces during installation.

7.12 Window operators – ensure window hold open equipment is suitable for application – friction stays do not work for large awning windows. In the case or large/heavy awning windows chain operators are required for example.

7.13 Ensure Hardware (handles) etc is suitable for the application – designers continue to pick chrome plated handles that look good when installed. No consideration is given to what they will look like after being used in a harsh salt environment for example.

7.14 All windows need to be “serviced” on completion – the tracks cleaned, rollers checked for proper operation, locks adjusted to ensure the door operates correctly and locks serviced. This is a typical defect where little or no effort is made to ensure the operable windows and doors are sliding and closing reasonably at the time of construction. It is important that this is completed and personally checked by the site manager. It is an UNNECESSARY defect that reflects on our attention to detail at handover and post construction.