- 2 Minutes to read

- Print

- PDF

7. Roof Fixings

- 2 Minutes to read

- Print

- PDF

Screws

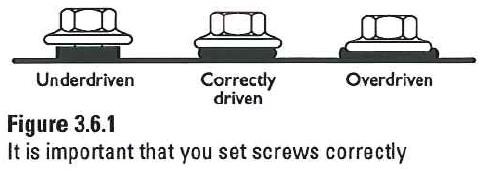

7.1 Use correct corrosion resistant class, length and gauge roofing

screw with black EPDM (a synthetic rubber) seals driven to a

moderate compression of the seal to the roof, and use the

required cyclone washers/clips to secure the roof. When fixings

are OVER DRIVEN they create ponding. When they are

UNDERDRIVEN the seal does not work.

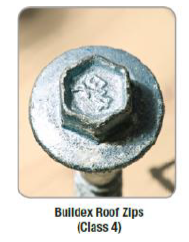

7.2 Fixings are detailed in AS3566 – with class 4 the highest standard documented, but class 5 is now available, as a result of a number of failures with Class 4 fixings in marine environments and the need for better fixings. The Building Code of Australia requires class 5 fixings in severe marine environments.

7.3 The standard required by Hutchies is that Roofing/wall cladding that is located within 1000m of a marine/harsh environment is to use fixings of Class 5 i.e.: Climseal 5 (or stainless finish for stainless base metal wall cladding where required by Colorbond), class 4 in all other areas. CHECK with the fixing manufacturer if in doubt. STAINLESS fixings

are NOT compatible with standard or Ultra Colorbond roofing. The class is shown on top of the screw (if not do not use).

STAINLESS FIXINGS TO STAINLESS ROOFING WITHIN 100M OR WALL CLADDING WITHIN 500M OF A HARSH ENVIRONMENT

CLASS 5 FIXINGS TO COLORBOND /ULTRA ROOFING WORKS WITHIN 1000M OF A HARSH ENVIRONMENT (MARINE/INDUSTRIAL)

CLASS 4 FIXINGS TO ALL OTHER AREAS

7.4 Compatible fixings

- Colorbond and Ultra sheeting - use aluminium rivets and zinc tin alloy coated fixings (class 3-5) – STAINLESS IS NOT COMPATIBLE

- Stainless Colorbond sheeting (wall cladding 300m from marine environment) - use stainless fixings only DO NOT USE CLASS

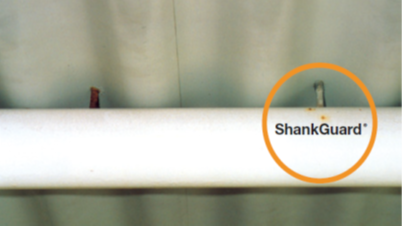

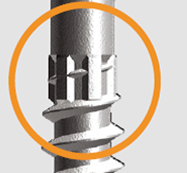

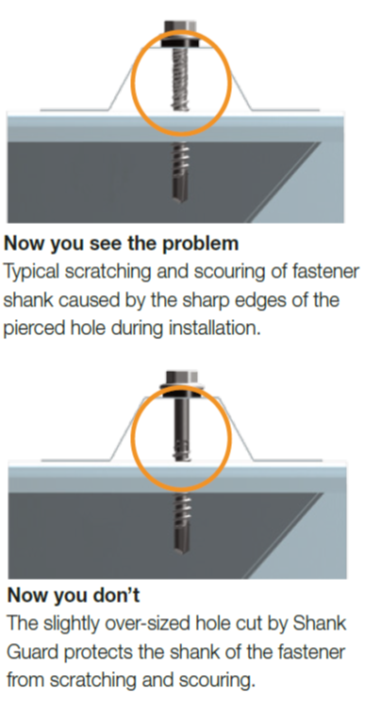

7.5 Ensure that fixings have a “SHANKGUARD” which prevents the screw rusting out underneath the sheet. The shank guard MUST be at the top of the thread NOT halfway up the shank. Below is ACCCEPTABLE

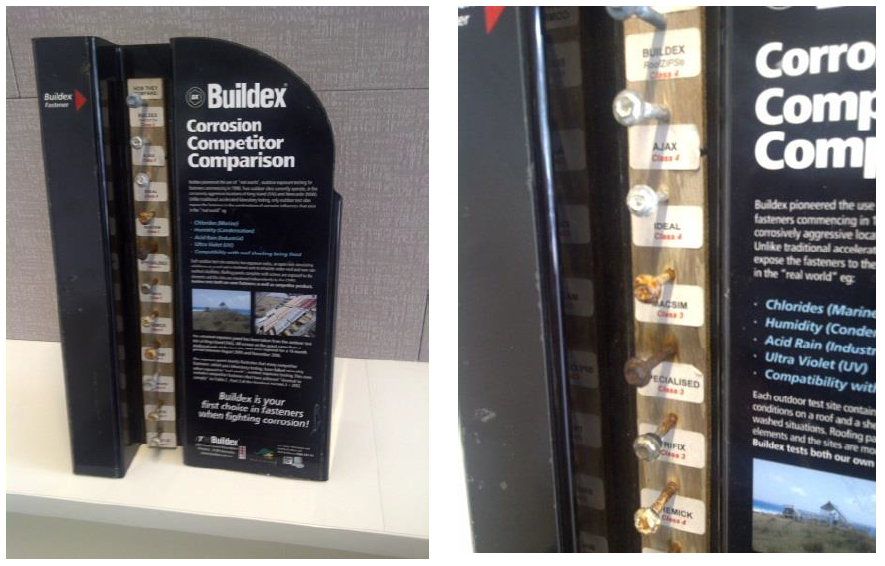

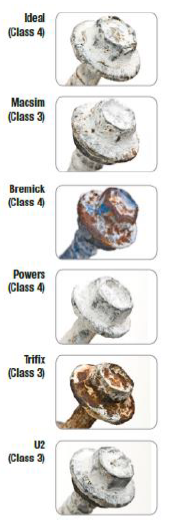

7.6 Different manufacturers mean different qualities of product.

7.7 Some claim to meet the Australian standards – but the reality is that most just don’t – some imported product are “inconsistent “at best. The roofing suppliers all recommend only one company for fixings.

7.8 As can be seen from the “real world” tests – there are some readily available screws from the local hardware that don’t last just 16 months in a harsh environment.

7.9 A simple roofing screws comparison cost for different classes across various manufacturers show that using a good quality screw is a NEGLIABLE cost and simply not worthwhile compromising the project for – in the order of $100 difference between suppliers for the same class of fixing and to use a better class of fixing, only $200 more.