- 3 Minutes to read

- Print

- PDF

8. Tiling

- 3 Minutes to read

- Print

- PDF

8.1 There are four main aspects to tiling;

• Slip resistance

• Falls

• Tile set out/format

• Surface Tension of water on the tiles

8.2 All four aspects influence each other considerably, and as such every wet area requires careful consideration to ensure the finished product meets safety, drainage and aesthetic requirements/expectations.

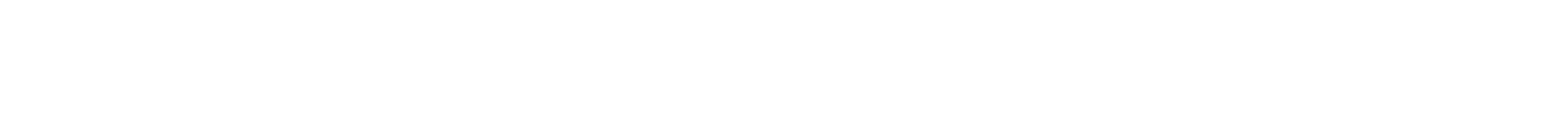

8.3 For safety of users of the wet area, tiles should have a good resistance against slip. Tiles should be tested for compliance with the provisions HB197 and in the absence of any other advice – domestic bathrooms should be R10 slip resistance.

8.4 Slip testing will be carried out on nominated public areas in commercial and industrial areas and certified on completion of shopping centres, hotels, residential complexes and building where reasonable public access is available.

8.5 Ensure we provide a non-slip maintenance schedule on non-slip treads/surfaces to stairs at the time of handover within the Maintenance Manual stating method and frequency of cleaning and re-application of products as required by the Manufacturer. This is essential in dissolving our on-going risk.

8.6 To remove water, the floors need to be laid to minimum falls, which is further dictated by the set down and size of the bathroom. The reality is that MOST wet areas are NOT laid with sufficient falls.

8.7 The tile set out/format further affects all of the above – a large format (greater than 200 x 200mm) floor tile cannot be readily laid to a cross fall and typically “splits” - cutting tiles in diagonal shapes to achieve a fall – is not preferred aesthetically (as some ceramic tiles do not provide an acceptable cut edge), has less grout lines (for increased slip resistance) and typically there is an aversion to cutting tiles around the floor waste (“cutter” tiles).

8.8 Large format tiles are NOT preferred for most wet areas. 100 x 100mm tiles with an R10 slip rating have additional grout lines and can be laid easily to create cross falls. Far more ideal for a public access wet area than say a 450 x 450mm polished marble tile! A $5m house on the other hand – will want a 600 x 600 polished marble tile – and consideration to a non-slip sealer, one way falls to a trench drain to delete the need to cut the tiles.

8.9 It is important to get the right balance between all aspects – but as a minimum;

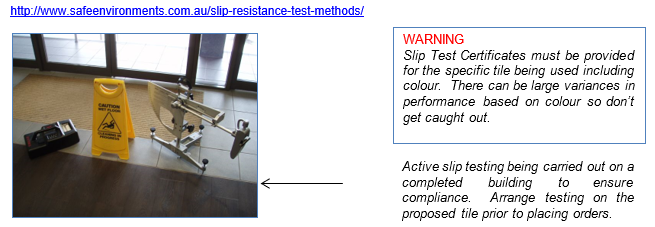

• Shower floors should have a minimum recommended fall of 1:60. Bathroom floors should have a minimum recommended fall of 1:80 (AS1428.1 requires 1:80 in bathroom floors)

• Tiles around the floor waste will be cut to achieve falls if the tiles used exceed 100mm x 100mm.

Above – waste with cut tiles

8.10 The rim of the floor waste will be 2mm below the finished tile level. This is important as if the waste is slightly higher than the tile – the water will POND at the waste and INCREASE the depth and incidence of surface tensions related water.

8.11 All tiled areas will contain a full perimeter control joint a minimum of 6mm wide. The control joint will be grout, adhesive and debris free.

8.12 All tile spacers will be removed prior to grouting as required under AS3858.1.

8.13 All tiles will be fully grouted with proprietary water resistant grouts or epoxy (as the case may be for kitchens etc).

8.14 ALL junctions of ALL finishes/surfaces are to be silicone sealed with a mould resistant silicone, colour matched as required to provide suitable aesthetic results.

8.15 Surface tension of water on tiles is the remaining water that sits on the tiles even when there is falls to a waste - where the water “sticks” to the tiles and does not drain away. There is insufficient fall in the floor to completely remove all water. This residual water is only removed by evaporation.

8.16 Surface tension is defined by the BSA as water that is not as deep as a 20 cent piece laid flat in the water immediately after water application OR water that evaporate within 2 hours of the water application. It is referred to in AS3740.

Above – surface tension around a waste