9.1 Concrete must reach a moisture content of less than 5.5% or a relative humidity of 70% for the application of vinyl in accordance with Australian Standard 2455.

9.2 Carpet can be laid with adhesives (same requirements as vinyl glue) or laid over an underlay. In both cases the moisture hydrating from the concrete can affect the carpet itself (mould).

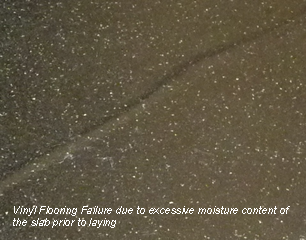

9.3 After conducting the correct tests; if in doubt, and as good practice – do a number of test areas and observe the actual adhesion by looking for glue failure/bubbling of the vinyl and/or a destructive pull off test (try and remove the vinyl to determine the adhesion). It’s not a definitive test by any measure, but it does provide a guide as to what is likely to occur.

9.4 The typical vinyl glues are WATER BASED adhesives with a solids content of around 75% and water of around 25%. Using these on high moisture content slab would essentially dilute the adhesive and cause failure of the glue. The risk is that the glue “deteriorates” into a wet glue mix instead of setting and adhering as glue should.

9.5 The glues are water based because they are required to be low VOC (volatile organic compounds) – in other words – less solvents which is a part of environmentally sustainable construction requirements. Think of it like going from lead paint to water based – it’s different and has its limitations, but it’s a better outcome generally.

9.6 In the case that there is insufficient time in the programme to achieve the required moisture content, it is necessary to use a slab primer/sealer to prepare the slab to accept the vinyl glue can bond to. This costs in the order of $20/m2 or more and can add significant costs to the project on Coles and Woolworths stores or the like! Products that are designed for this purpose include Ardex WPM 300 Hydropoxy green slab prep.