Recommendations for Shower Screen Installation

(Informative)

The following recommendations are provided for the benefit of screen fabricator and

installer, and the home owner/user:

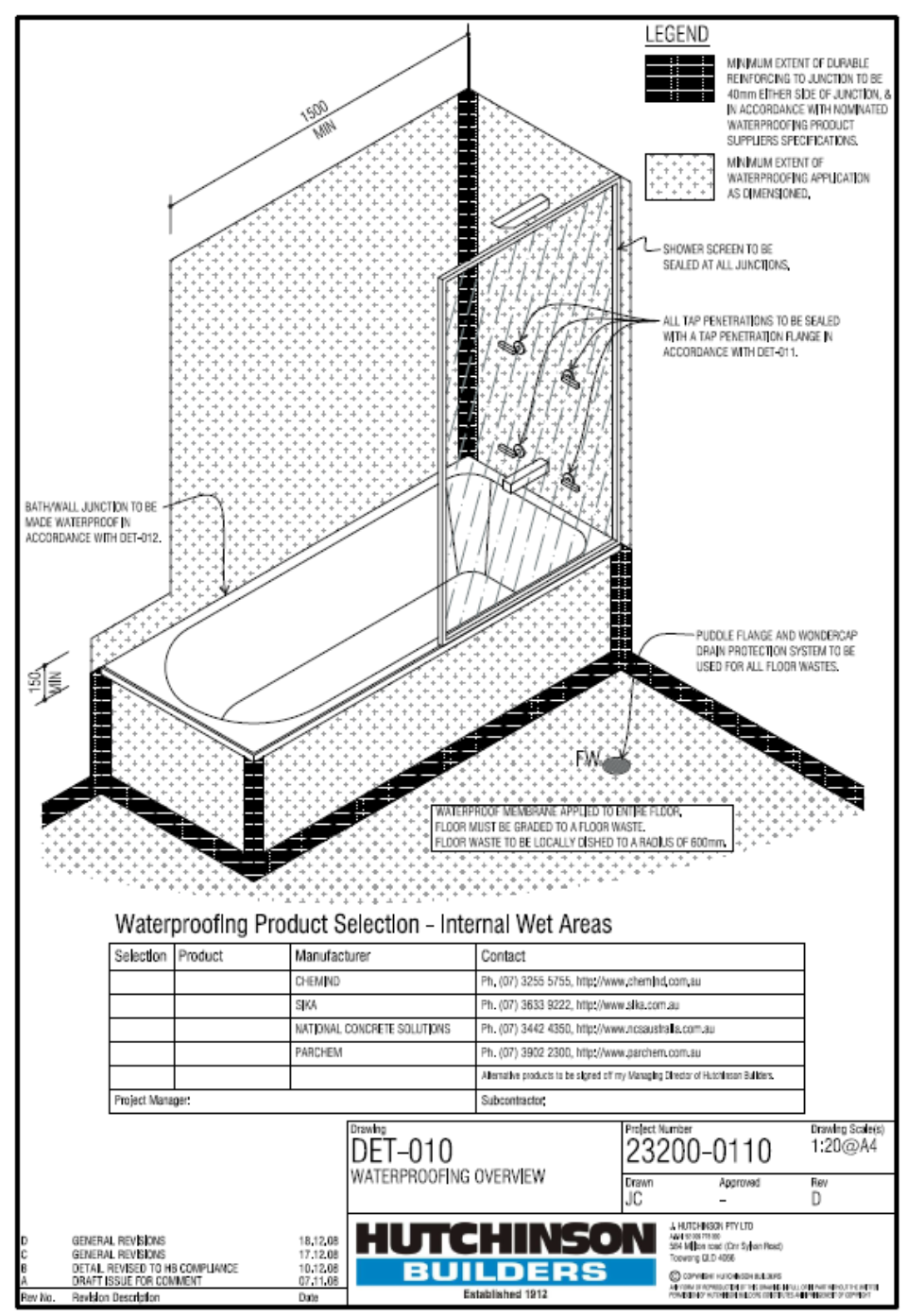

(a) Shower screen installation should comply with AS 3740.

(b) To ensure stability and safe performance of frameless shower screens, glass gussets,

braces and supports at the head of the frameless glass may be necessary.

(c) While patch fittings provide required strength and appearance, the fixed glass panels

in a frameless shower screen may be attached to the wall and floor with a securely

fixed channel. The glass should be anchored firmly to the channel with glazing

wedges or structural grade silicone.

(d) The hardware design should be such that the ‘cut-outs’ or fixing holes in toughened

safety glass anchor the glass to the fittings thus reducing the potential for a hinged

frameless door to sag, which can result in glass to glass and glass to floor contact.

The hardware design should also include gaskets to prevent glass to metal contact.

(e) Unframed doors should be installed in such a manner as to avoid the edge of the

glass, which is the part of glass most vulnerable to breakage, from coming into

contact with the stile or floor.

(f) A frameless glass wall panel up to 2100 mm high should have a minimum of two

mechanical fixings to the wall at 1700 mm maximum spacing. Panels exceeding

2100 mm high require additional fixings at 1700 mm maximum spacing. This is in

addition to silicone, which provides some stability to the glass as well as sealing of

glass to wall tiles, etc. Screens can be attached to the floor allowing for minimum

3 mm clearance with either structural silicone or minimum 2 mechanical fixings at a

maximum spacing of 1700 mm.

It is recommended that homeowners regularly inspect the following aspects of the operation

of a frameless shower screen:

(i) Ensure a minimum of 3 mm clearance is maintained between all edges of a frameless

glass door and the fixed panel and or wall and the floor.

(ii) Check the tightness of the screws and clamp/patch and hinge fittings.

(iii) Check the operation of the hinges to ensure that they hinge freely and are not bound.

(iv) Replace scratched or damaged glass.

(v) Ensure that, when making alterations to a shower area, frameless shower screen glass

door/s do not make contact with objects that may cause the frameless glass door to

fracture.

When reglazing or replacing glass it is recommended that Grade A safety glass be used

Introduction

During the installation of the waterproof membrane, particularly liquid membranes, there is frequently conjecture between the Concreting Contractor and the waterproofing contractor in the assessment of the surface finish.

The simple reason for this is that Builders normally specify the concrete finishes required on a projec in accordance with AS3610. For an architectural project where membranes are installed the normally expected standard is Class 2 which is designed to define the limits of flatness and smoothness.

The Concreting Contractor finishes his work to this standard however complying with the requirements of this standard does not necessarily produce a surface that is suitable for a membrane application.

The waterproofing contractor tenders the installation of the membrane on the basis that the surface provided is fit for a membrane application and conflict arises.

The purpose of this Bulltin is to define the requirements for a surface finish suitable for a liquid membrane application and to outline the common differences that can exist between a AS3610 Class 2 surface finish and a finish suitable for a membrane application.

Liquid membrane Application

The primary requirements of an effective liquid membrane application involve achieving good adhesion to the substrate and the application of a uniform mimumum dry film thickness over the entire surface to be waterproofed.

To achieve this there are a number of minimum requirements of the substrate surface in addition to it being sufficiently structurally sound to support the membrane application.

Surface Cleanliness

The substrate surface must be clean and free from loose particles (dust and dirt) and all surface contaiminants that may hinder the achievement of good bonding characteristics.

The requirement not only refers to the dirt and dust tracked in from adjacent areas but also refers to the micro-surface finish of the concrete that may be loosely bond due to the finishing process of the concrete. As an example, if the finishig of the concrete is carried out with excessive bleed water remaining, the cement fines are drawn to the surface and create a weakly bound micro-surface on the concrete.

Surface Porosity

A liquid waterproof membrane is designed to achieve a mechanical bond by penetrating the micro-surface of the substrate and keying firmly to the concrete. To achieve this, the surface must obviously be open pored (porous) to allow the required penetratio into the concrete.

Highly polished or overworked concrete are not surfaces that are suitable for a membrane application.

Care should also be taken with grinding that can turn a porous surface into a low permeability surface by pressure fine particles into the pores of the concrete.

Surface Finish

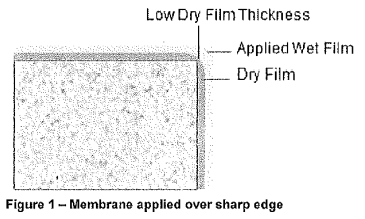

Liquid membranes are applied as combination of solid film forming material combined with a carrier solvent (frequently water). After application the film possesses some degree of self-leveling or self-smoothing properties as the carrier solvent evaporates leaving the dry film.

It is therefore essential, to achieve a uniform dry film thickness, that the surface finish be relatively smooth and free from sharp edges or significant protrusions or intrusions.

When applied to a sharp edge (Figure 1), a liquid membrane will tend to flow away from the edge as it dries resulting in a low dry film thickness being achieved at the sharp edge. This is typical of any liquid material application.

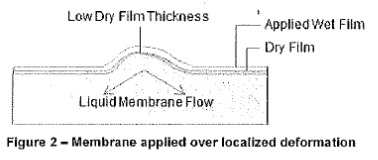

For the same reasons, when a membrane is applied over a localized deformation, be it intrusions or protrusion, the liquid material will tend to flow from the high points during the drying process leaving a film with a lower dry film thickness at the peak of the deformation.

Surface Accessibility

Surfaces to which a liquid membrane is to be applied must be easily accessible to a roller or brush application. This may appear to be an obvious criterion however it is frequently overlooked in the surface preparation.

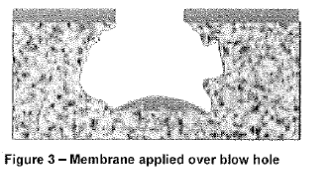

In the case of off-form concrete the resulting surface frequently has numerous voids commonly called blow holes. These can either be visible voids or voids hidden under a thin cementitious skin whihc is very weak and unsuitable for a membran application.

Apart from the fact that these blow holes normally exhibit sharp edges as described above, they also frequently result in inaccessible surfaces within the void.

Figure 3 represents the result when a memrane is applied to the surface is that there are significant surfaces within the void that are totally uncoated. This is unavoidable when the interior of the void is not accessible.

Surface Requirements for Membrane Application.

In summary therefore, the surface requirements suitable for a membrane application are:-

a. Structurally sound

b. Free of dust and other contaminants

c. Porous

d. Free from localized surface defects such as protrusions and intrusions.

While the first two or even 3 of these requirements are considered the waterproofing contractors responsibility, the fourth is frequently considered by the waterproofing contractor as being part of the builder's responsibility to provide a suitable surface.

Concrete Finish in Architectural Building

As outlined previously a building specification normally calls up a concrete finish in accordance with Class 2 of AS3610 for an architectural building.

AS3610 is principally concerned with the broadspan surface finish as far as smoothness and levels and less concerned about the localised defects for which it allows a certain tolerance.

AS3610 Class 2 therefore allows a certain density of blow holes. Blowholes present a major problem for a successful membrane applicaton as described above so the surface needs to be totally free of those defects for the surface to be suitable for a membrane application.

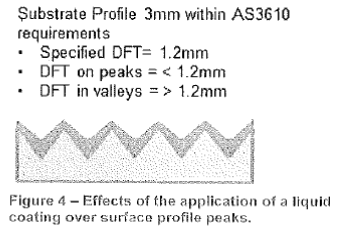

AS2610 Class 2 also allows for a surface deviation over extended lengths. While the extent of these deviations spread over the extended length presents no problem for a successful membrane application, when th extent of the deviation is limited to an isolated area it does become a problem. A fine scabbled surface may conform to AS3610 but is unsuitable for a membrane application due to the numerous peaks whithin a small localised area.

Responsibilities

Standard construction procedure is to specify the concrete finish required in accordance with AS3610.

Waterproofing requirements for concrete finish may exceed the requirements of AS3610.

Adjustments to the concrete surface profile may occur after pouring, such as adjustments to set down areas, resulting is damaged surfaces.

Damage to and contamination of the surface can occur between the Concreting Contractor handover and the waterproofing contractor commencing work.

The following responsibilities are therefore proposed to avoid conflict and unexpected costs being incurred by any party.

Builder Responsibility

- Builder is responsible for nominating the standard of surface finish required from the Concreting Contractor.

- Builder is responsible fo rnominating a standard of surface finish to be supplied to the waterproofing contractor at the time of tender.

- Builder is responsible for providing a surface finish in accordance with AS3610 to the waterproofing contractor.

This means the builder is responsible for the costs of remediating and damage resulting for other trades that occurs between the Concreting Contractors hand over and the builder's handover to the waterproofing contractor restoring the surface to a standard conforming to the Class of surface nominated under AS3610.

Remediation includes the removal of surface contaminants such as render deposits or other spills ad the remediation of surface damage such as step breakouts or surface impact damage.

Concreting Contractor Responsibility. - The Concreting Contractor is responsible for handing over a surface finish in accordance with the specified Class under AS3610 to the Builder.

This includes the remediation of any changes to the surface after pouring such as set down area adjustments to conform to specified Class under AS3610.

Waterproofing Contractor Responsibility - The Waterproofing Contractor is responsible for all surface remediation necessary to upgrade the surface finish from the specified finish in accordance with AS3610.

The waterproofing contractor should therefore allow in tender

- for filling surface defects such as blowholes to the extent permitted the under the relevant class of AS3610.

- For beveling or rounding sharp corners such as steps for set down edges

- for either smoothing or applying additional membrane over short distance surface profile deformations allowable under the relevant class of AS3610 to achieve the required dry film thickness over the peaks. (Ref Figure 4)

While the above defines where responsibilities lie in the process of achieving a suitable surface finish to the concrete, it does not obviate disputes regarding the assessment of surface in relation to AS3610. This can only be resolved by the appointment of a mediator to which all parties agree to abide.