The below methodology is to be used as a management tool to establish the compliance of cladding products/systems.

All cladding products must be reviewed as per this document and approved PRIOR to plaing order, whether or not it's a Design & Construct or Construct only contract.

Step 1 DETERMINE THE BUILDING CLASSIFICATION

- Refer to Section A, Part A3 of the NCC. If the class of your building is between 2-9 then the below steps can be used for selecting external claddings;

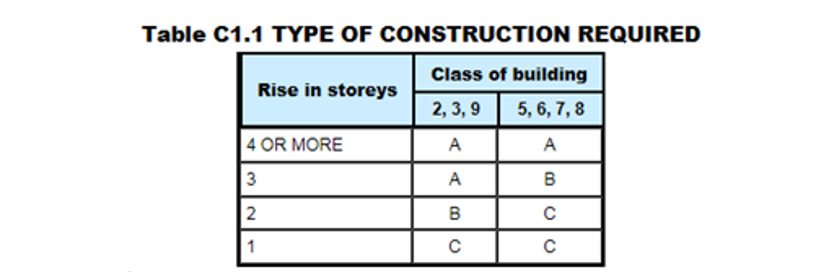

Step 2 DETERMINE THE TYPE OF CONSTRUCTION

- Refer to section C of the NCC, and determine the type of construction that is required for the building classification from table C1.1

Step 3 ATTACHMENT OR WALL? - To avoid confusion ALL cladding to Type A & B construction are to be non-combustible regardless of being a wall or an attachment unless there is clear FER/Certifier/authoirty approval for an alternative solution and this is signed off by The Quality Team and Team Leader.

- All Type C buildings should be use a non-combustible 1530.1 cladding to exits and subject to The Quality Team and team approval - use non-combustible (preferred) or fire resistant (FR/A2) ACP products and Kingspan or equal wall PIR panels with AS 1530.3 testing to other areas.

Step 4 COMBUSIBILITY OF EXTERNAL WALLS - TYPE A & B

- Specification C1.1 in section C of the NCC states - For Type A & B construction, it is a requirement that all external walls are non-combustible.

- Non-combustibility of a material is defined as - not deemed combustible as determined by AS 1530.1.

- All claddings that are proposed to be used on the external wall of a Type A or Type B construction must be tested in accordance with AS 1530.1 (unless the material is noted in C1.12)

- Evidence of testing by NATA approved independent testing laboratory in accordance with this standard must be provided.

- Specification C1.1 also outlines the requirements for fire resisting construction. Table 3 for Type A, Table 4 for Type B & Table 5 for Type C. Each building element listed in the tables, must have an FRL not less than that listed in the Table for the particular Class of building concerned.

- If it is determined that the cladding forms part of an external wall system that does not require an FRL, then a fire test report (in accordance with AS1530.3) must be produced for the entire system that the external cladding forms part thereof in order to undertake a review.

Step 5 COMBUSTIBILITY OF EXTERNAL WALLS - TYPE C

- For Type C Construction the cladding must technically meet the requirements of Clause 4 of Specification C1.10 which sets out requirements in relatio to the fire hazard properties of linings, materials and assemblies in Class 2 to 9 buildings.

- Above this is Fitness for purpose considerations so the HB position is to use non-combustible cladding at exits and preferably to all locations, however Fire resistant cladding to AS 1530.3 tested to C1.10 is acceptable.

Step 6 - CONFORMITY UNDER THE ABCB CODEMARK SCHEME

- CodeMark certificates are the first step in ensuring the product is able to be used in Australia but does not give you confirmation that the Aluminium Composite Cladding (ACP) or other cladding can be used on the external Facade / fabric of the building unless the Codemark states it has been tested in that specific circumstance. You need to establish the suitability of application for every product for your particular building.

- A CodeMark certificate will generally state which section of the NCC that the product complies with, the group member of the material, the fixing method that is required for the product, and any limitations to the certificate.

- Essentially a CodeMark certificate will provide all or part of the information that is required for steps 4 & 5 above.

- A CodeMark certificate and all referenced documents in the certificate must be provided to undertake a review.

Step 7 - FIRE ENGINEERING REPORTS

- Locate any Fire engineering advice provided to date that considers the claddings and any limitations around exits etc.

Step 8 - FIXING METHOD

- Determine fixing method (Cassette or Adhesive tape) and procure copies of manufacturer tested details of the installation.

Step 9 - SEEK APPROVAL OF DRAFT PROPOSAL

- Consolidate a "DRAFT" package for the proposed cladding selection that includes the information that is obtained from steps 1 to 6 above (Class/Type, test reports etc), as well as set of marked-up plans showing the extent of the proposed claddings and any existing FER information.

- Seek approval from The Quality Team & your Team Leader.

The Quality Team - QualityTeam@hutchinsonbuilders.com.au

Step 10 - SEEK APPROVAL FROM CERTIFIER/BUILDING SURVEYOR/FIRE ENGINEER

- Submit approved cladding proposals for your uilding to your Building Certifier/Surveyor for approval. (Include the following with your submission to your Building Certifier/Surveyor: marked-up plans, all test data, fixing methodology, CodeMark certificate & The Quality Team acceptance).

- Once approved this becomes the project Approved Cladding Documentation.

Step 11 - PREPARE PROJECT SPECIFIC SHOP DRAWINGS

- Prepare site specific shop drawings as required showing details of of cladding, battens and fixings systems for QA approval by The Quality Team and consultants.

STEP 12 - SAMPLES/CONSTRUCT PROPTYPE FOR QA REVIEW

- Procure samples of cladding, battens and fixings systems and where required, construct a prototype on site, for QA approval by The Quality Team.

- This is particularly required to connections to windows and the like.

STEP 13 - COMPLETE WORKS, as per approved specification

- Complete all cladding works as per your approved documents.

- Perform regular QA checks, to quality of application is maintained as per approved proto-type and materials are installed correctly.

- Include complete Cladding Documentation with Hutchinson handover manual.

- When inspecting/co-ordinating the works, note client variations, discrepancies and clashes may all alter the detailing. Repeat process as necessary to replan cladding specification to ensure it is compliant.