Precast panels are connected to other structural elements including other precast panels using an array of connections in two categories as below;

Type 1 – Precast to other structures other structures as built

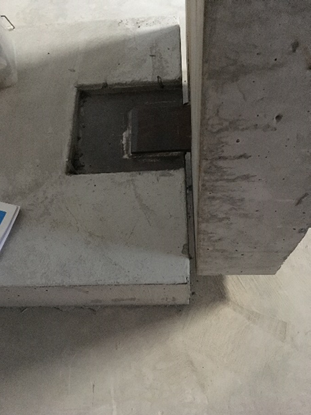

• Structural steel plates/brackets from precast to precast, insitu + structural steel support structures

• Dowel connections from precast to insitu structure

Type 2 – Precast to other in-situ structures to be built

• Cast in ferrules/connectors to connect reinforcement to the precast to connect to insitu concrete structures

• Cast in reinforcement bars in the precast to connect to insitu concrete structures

Type 1 connections place two constructed elements together and require a tolerance to allow the connection to be successful

It is critical to identify the required tolerances that will be encountered on site when installing the works so that any impact on the detailing and engineering of the connection. Where precast is installed against in-situ works 20mm tolerance is typically and against structural this is typically 10mm+ and requires packing. With dowel bars the dowel sits with in a larger cast in hole for grouting – to provide tolerance to the install.

These tolerances need to be considered in the engineering of the works and shown on the for construction drawings

Steel connections also need to be checked for any fire rating requirements that may impact on the detail as well.

Type 2 connections require the precast to be supported and braced/propped to resist all construction and environmental loads while the insitu element is constructed up to the precast element and cast in place together

These connections require careful consideration with temporary works engineering including formwork to ensure the precast element can be supported successfully until the insitu element has reached sufficient strength to support the precast element in its permanet design.