- 2 Minutes to read

- Print

- PDF

Render - General Principles

- 2 Minutes to read

- Print

- PDF

Render is a thin (typically 5-10mm) coating of sand and cement mixture over block work, concrete or fibre cement board to provide a smooth hardwearing and “almost” seamless paintable finish to the façade elements of buildings.

There are 4 main issues of concern with rendering details;

Delamination

Is Render that becomes “drummy”. Tapping the render and hearing a ‘hollow’ sound that resonates from the gap between the thin render coating and the substrate as a result of de-bonding. This is usually as a result of one of the following -

1. Failure to remove contaminants from the surface of the substrate through correct surface preparation. (such as form release oil, curing compounds, dust and the like)

2. Failure to apply a suitable “scratch” coat to smooth substrates to allow the render to have a “key” to adhere to the substrate.

3. Incorrect mix ratio of render (traditional or bag mix) weakening the material or not allowing for correct moisture content which is critical to absorption into the substrate of the mix.

4. Also the moisture content of the substrate can if too wet or too dry prevent the render from absorbing the mix and creating a solid bond/adhesion.

5. Failure to check that the render is compatible with the waterproof membranes applied to the substrate.

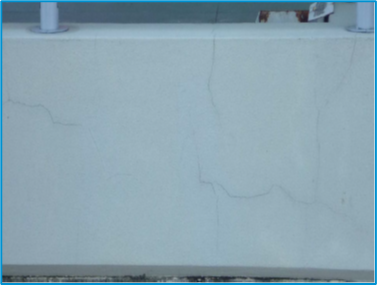

Drying Shrinkage Cracking

Render is wet cement based material and needs to “cure” from a wet mix when applied to the building to the final hard finished surface. Curing is the controlled “drying” out of the render. Render that is allowed to dry out too quickly will crack as it shrinks from the rapid removal of water causing excessive drying shrinkage. Retention of moisture in the render while the render is “curing” is required to ensure the render has the opportunity to achieve its design strength (MPA) and the adhesion is adequate.

To achieve this controlled curing of the render where subject to environmental conditions such as rain, sun and particularly wind a number of methods are available.

• Applying water through gentle spraying

• Working the surface with wet sponges (Only suited to small areas)

• Coverage with plastic sheeting

Jointing

Where the substrate has expansion, control or cold joints or where any movement is expected then the render must also have a joint installed to mirror exactly the substrate joints to prevent the expected and necessary movement in the substrate causing the render to fail. These joints are required to be sealed in both the substrate and the finished render surface to prevent water ingress into the building.

Cleaning Up

Render is a wet trade and is applied by hand. Typical render application results in render “droppings” on other works such as windows and lower level roofing. Plastic protect and tape window frames during render and painting works and wash off any over spray incidentally covered immediately.