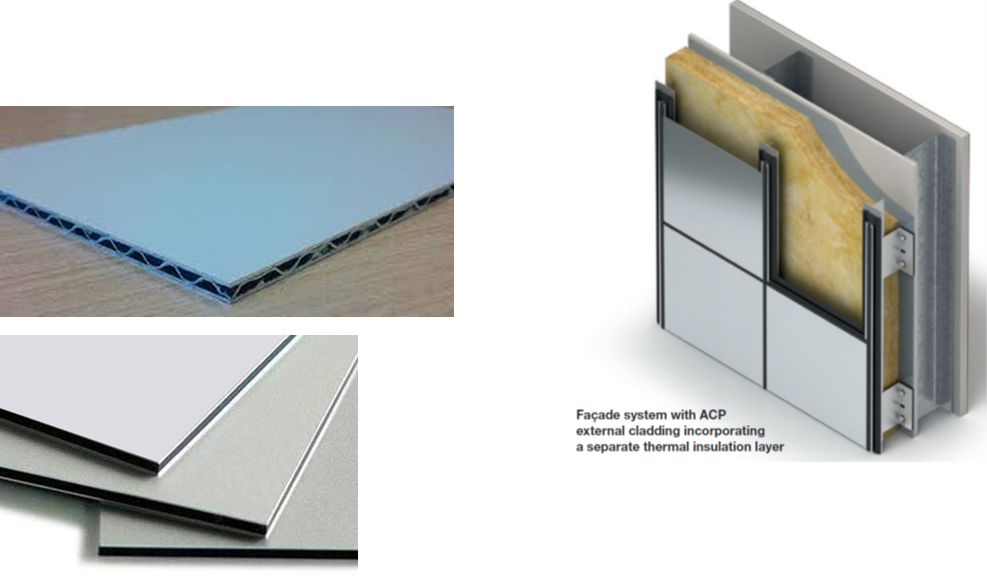

External Composite Wall Cladding Systems in this section are various lightweight solutions including:

ACP (Aluminium Composite Panels)

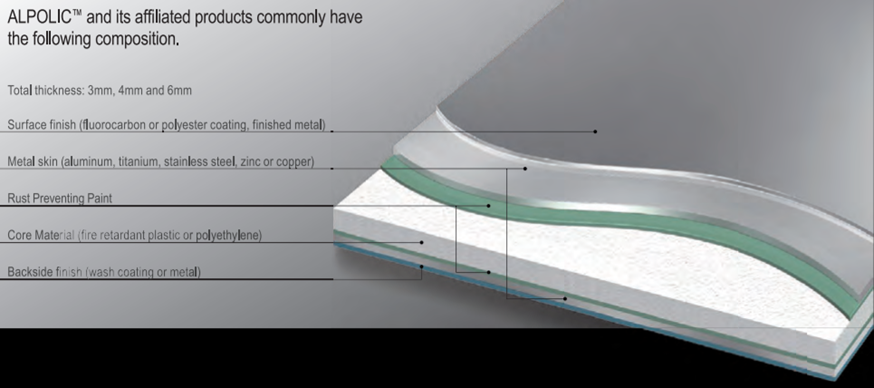

Also known as ACM (aluminium composite material) - there are 3 types:

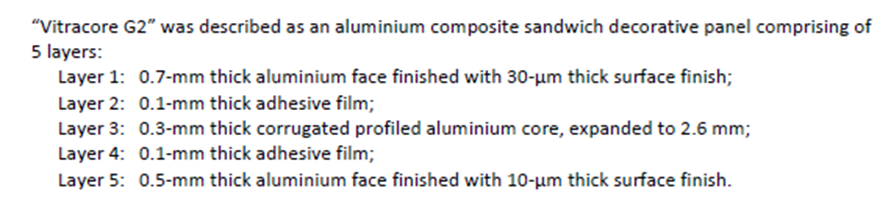

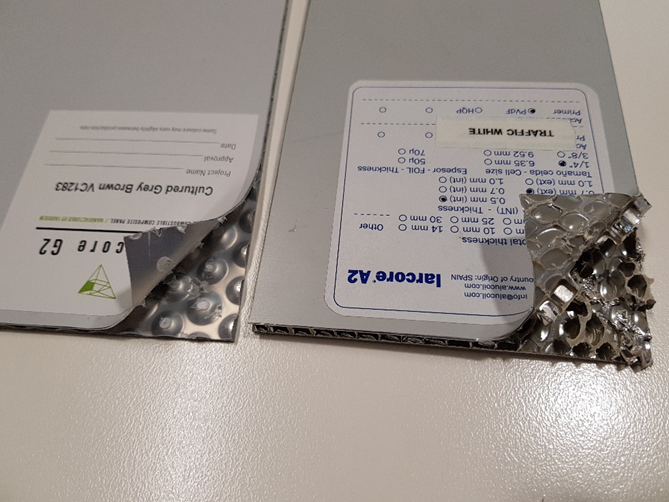

• Honeycomb core (non-combustible) (eg Vitracore) and

• mineral filled (limited combustibility) (eg Alpolic FR/A2, Alucobond FR/A2)

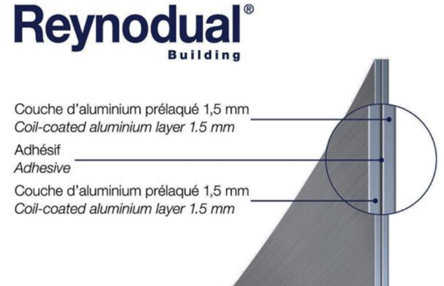

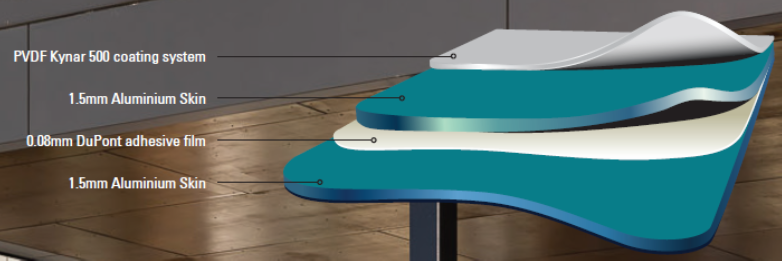

ALP (Aluminium Laminate Panels)

(eg Reynodual)

• two layers pre-finished aluminium sheet glued together (laminated)

SLP (Solid Aluminium Panel)

(eg Vitradual)

• Not a composite panel (single layer of aluminium) but is designed/tested/installed in same manner

Other solid metal products

• Copper cladding

• Zinc Cladding

Other composite panels (ie metal faced foam panels)

• Fire resistant PIR (polyisocyanurate) core foam panels (eg Kingspan)

• EPS (expanded polystyrene) Core foam panels,

• EPS - FR (EPS + fire resistant additive) Core foam panels (eg Bondor)

• PUR (Polyurathane) core panels

• Aluminum/copper/zinc cladding over insulation core

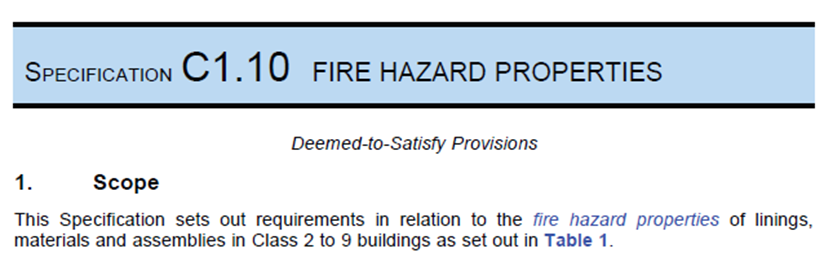

Compliance

With so many possible combinations of scenarios and solutions for external walls – it’s important to understand the selection process for a compliant system.

This section will only deal with the panel selection based on combustibility criteria – part J insulation, speed of construction, wind load resistance or any other factors other than combustibility are not considered in this document.

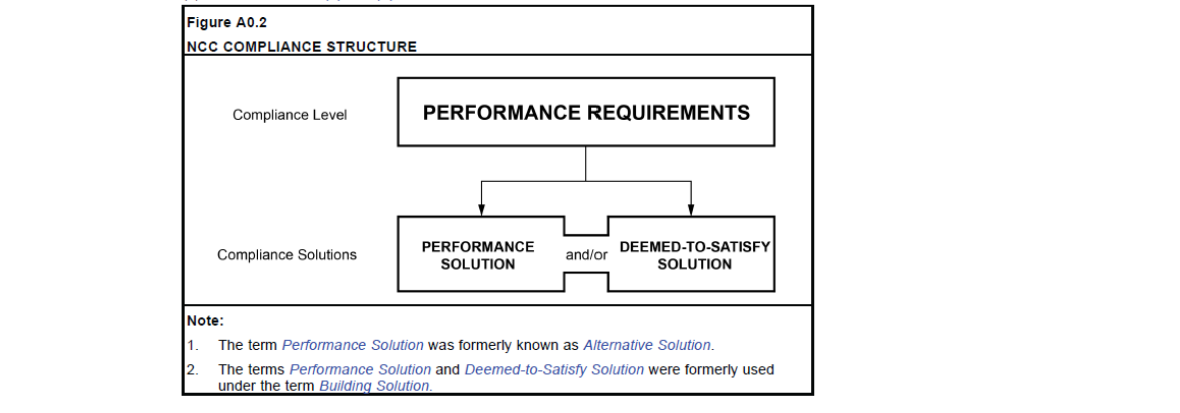

1. The NCC sets out the minimum requirements for a building and provides for DTS and/or performance solutions (Section A0.2/A0.3).

A0.2 Meeting the Performance Requirement

The Performance Requirement can only be satisfied by a -

a) Performance Solution; or

b) Deemed-to-Satisfy Solution; or

c) combination of (a) and (b)

A0.3 Performance Solution

a) A Performance Solution must -

i) comply with the Performance Requirements; or

ii) be at lease equivalent to the Deemed-to-Satisfy Provisions, and be assessed according to one or more of the Assessment Methods.

b) A Performance Solution will only comply with the NCC when the Assessment Methods used satisfactorily demonstrate compliance with the Performance Requirements.

2. A performance solution must be documented as per Clause A2.2 of the NCC

A2.2 Evidence of suitability

a) Subject to A2.3 and A2.4, evidence to support that the use of a material, form of construction or design meets a Performance Requirement or a Deemed-to-Satisfy Provision may be in the form of one or a combination of the following:

i) A report issued by a Registered Testing Authority, showing that the material or form of construction has been submitted to the tests listed in the report, and setting out the results of those tests and any other relevant informatio nthat demonstrates its suitability for use in the building.

ii) A current Certificate of Conformity or a current Certificate of Accreditation

iii) A certificate from a professional engineer or other appropriately qualified person which -

A) certifies that a material, design, or form of construction complies with the requirements of the BCA; and

B) sets out the basis on which it is given and the extent to which relevant specifications, rules, codes or practice or other publications have been relied upon.

iv) A current certificate issued by a product certificatio body that has been accredited by the Joint Accreditation Syste of Australia and New Zealand (JAS-ANZ).

v) ***

vi) Any other form of documentary evidence that correctly describes the properties and performance of the material or form of construction and adequately demonstrates its suitability for use in the building.

b) Evidence to support that a calculation method complies with an ABCB protocol may be in the form of one or a combination of the following:

i) A certificate from a professional engineer or other appropriately qualified person which-

A) certifies that the calculation method complies with a relevant ABCB protocol; and

B) sets out the basis on which it is given and the extent to which relevant specifications, rules, codes of practice and other publications have been relied upon.

ii) Any other form of documentary evidence that correctly describes how the calculation method complies with a relvant ABCB protocol.

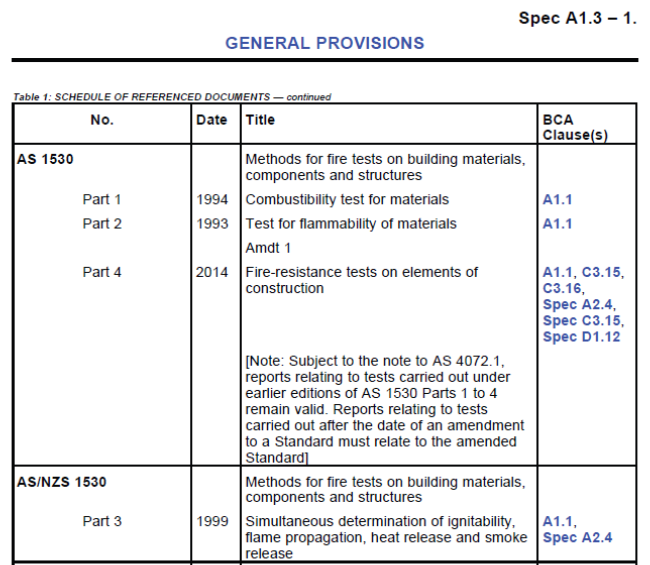

3. The NCC references certain Australian Standards which are mandatory as a part of the DTS solution and are also considered by a Performance solution (per NCC A0.5) to ensure its providing comparable performance.

For example – non-combustible (a DTS requirement using AS 1530.1) may be considered equal to very limited combustible (eg AS 1530.3 tested) + sprinklers by a fire engineer and the certifier/building surveyor – meaning either can be used – this directly affects what products that can be used.

4. In applying the NCC the certifier/building surveyor firstly nominates the CLASSIFICATION of the building – based on use of the building and considering multiple classifications in a single building (an office attached to a warehouse, or retail below an apartment tower for example)

A3.2 Classifications

Buildings are classified as follows:

Class 1: one or more buildings which in association constitute-

a) Class 1a - a single dwelling being -

i) a detached house; or

ii) one of a group of two or more attached dwellings, each being a building, sparated by a fire-resisting wall, including a row house, terrace house, town house or villa unit; or

b) Class 1b -

i) a boarding house, guest house, hostel or the like -

A) with a total area of all floors not exceeding 300m2 measured over the enclosing walls of the Class 1b; and

B) in which not more than 12 persons would ordinarily be resident; or

ii) 4 or more single dwellings located on one allotment and used for short-term holiday accommodation,

which are not located above or below another dwelling or another Class of building other than a private garage.

Class 2: a building containing 2 or more sole-occupancy units each being a separate dwelling.

Class 3: a residential building, other than a building of Class 1 or 2, which is a common place of long term or transient living for a number of unrelated persons, including -

a) a boarding house, guest house, hostel, lodging house or backpackers accommodation; or

b) a residential part of a hotel or motel; or

c) a residential part of a school; or

d) accommodation for the aged, children or people with disabilities; or

e) a residential part of a health-care building which accommodates members of staff; or

f) a residential part of a detention centre.

Class 4: a dwelling in a building that is Class 5, 6, 7, 8 or 9 if it is the only dwelling in the building.

Class 5: an office building used for professional or commercial purposes, excluding buildings of Class 6, 7, 8 or 9.

Class 6: a shop or other building for the sale of goods or the supply of services direct to the public, including -

a) an eating room, cafe, restaurant, milk or soft-drink bar; or

b) a dining room, bar area that is not an assembly building, shop or kiosk part of a hotel or motel; or

c) a hairdresser's or barber's shop, public laundry, or undertaker's establishment; or

d) market or sale room, showroom, or service station.

Class 7: a building which is -

a) Class 7a - a carpark; or

b) Class 7b - for storage, or display of goods or produce for sale by wholesale.

Class 8: a laboratory, or a building in which a handicraft or process for the production, assembling, altering, repairing, packing, finishing, or cleaning of goods or produce is carried on for trade, sale, or gain.

Class 9: a building of a public nature -

a) Class 9a - a health-care building, including those parts of the buidling set aside as a laboratory; or

b)** Class 9b** - an assembly building, including a trade workshop, laboratory or the like in a primary or secondary school but excluding any othe rparts of the building that are of another Class; or

c) Class 9c - an aged care building.

Class 10: a non-habitable building or structure -

a) Class 10a - a non-habitual building being a private garage, carport, shed, or the like; or

b) Class 10b - a structure being a fence, mast, antenna, retaining or free-standing wall, swimming pool, or the like; or

c) Class 10c - a private bushire shelter

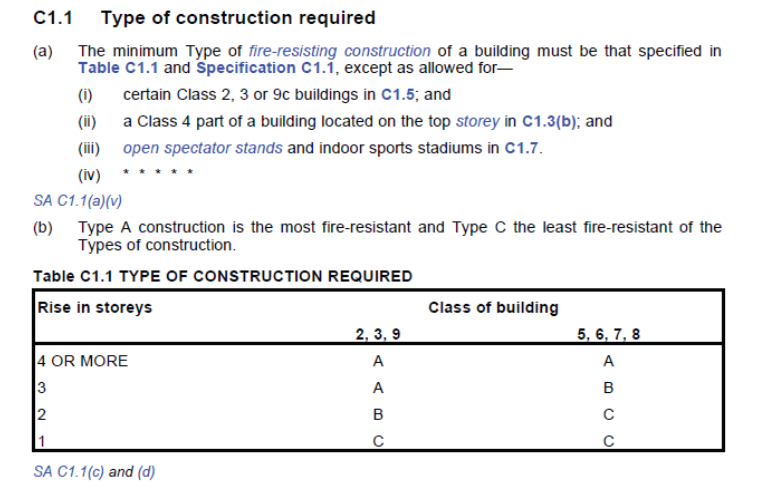

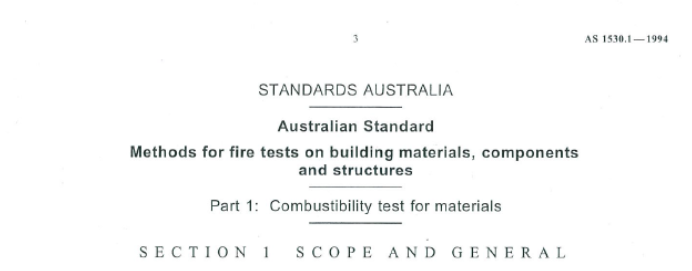

5. Next is Part C1 of the NCC – selecting the TYPE of construction for fire resistance – there are 3 types – Type A (the most fire resistant), Type B and Type C (the least fire resistant) –they are directly linked to the Classification of building and the size of it/any fire compartments in it

6. These composite wall panel systems may

a. be an aesthetical attachment to the building – ie if the cladding was removed the building would still perform to meet the requirements of the NCC to resist structural loads, prevent water penetration etcfor example an ACP cladded wall over a waterproofed block or concrete wall system (below) or a zinc cladding over a fully framed and sealed wall where the zinc is an attachment (below and below right) because the wall performs it its there or not

Or a decorative cladding over a roof as below (the roof meets NCC – the ACP is an attachment in this case

b. be an integral part of the wall system complete – for example;

• a Kingspan or Bondor foam wall system that spans between structural elements but forms the entire wall system or

• A Vitracore G2 or Zinc non-combustible cladding battened over lightweight stud framework with sarking and insulation and an internal lining

The ABCB Advisory note at the back of this document describes the differences and impact on selection

The CSIRO reference document provides similar clarity (extracts below)

For buildings requiring Type A and B construction the BCA Deemed to Satisfy provisions addresses two common cases relating to fire performance of external walls:

- The cladding is th exterior wall or part of the wall. (BCA Specification C1.1, Sections 3.1(b) & 4.1(b) apply)

- The cladding is an attachment to an exterior wall having the required FRL. (BCA Specification C1.1 Clause 2.4 applies)

- The term "external wall" is defined in teh BCA as "... an outer wall of a building which is not a common wall".

- If the cladding/lining/ other item is removed and the remaining structure no longer functions suitably as an external wall (for example, the remaining strucutre has no fire resistance level, is unable to prevent the penetration of water, is unable to resist wind loads, or in certain applications cannot meet acoustic requirements), then it is considered an integral part of the external wall, and BCA Specification C1.1, Sections 3.1(b) & 4.1(b) applies.

- If the cladding/lining/other item is removed and the remaining wall system still functions as an external wall then Spec C1.1 Clause 2.4 applies.

Why the differentiate them? ….If the cladding is an attachment it may not need to be a non-combustible element

If it’s a part of the wall – in Type A & B construction the cladding must non-combustible. (AS 1530.1 tested)

If its an attachment in Type A & B construction it ‘may’ be permitted as combustible to the limits in Clause 2.4 (AS 1530.3 tested) and noting this cannot be used around exits etc

Type C should be at a minimum limited combustibility to the values in Clause 2.4 (AS 1530.3 tested). Obviously there is no technical issue with using a non-combustible product on Type C construction as a preferred outcome.

For simplicity HB are progressing with ALL claddings to TYPE A & B construction are to be non-combustible regardless of being a wall or an attachment unless there is clear FER/Certifier/authority approval for an alternative solution and this is signed off by The Quality Team and Team leader

All TYPE C buildings should be use a non-combustible 1530.1 cladding to exits and subject to the Quality Team and Team Leader approval – use non-combustible (preferred) or fire resistant (FR/A2) ACP products and Kingspan or equal wall PIR panels with AS 1530.3 testing to other areas.

7. In type A and B there is a requirement for the external walls to be ‘non-combustible’ whereas in Type C there is no requirement for non-combustible materials

3. TYPE A FIRE-RESISTING CONSTRUCTION

3.1 Fire-resistance of building elements.

In a building required to be of Type A construction-

a) each building element listed in Table 3, and any beam or column incorporated in it, must have an FRL not less than the listed in the Table for the particular Class of building concerned; and

b) the external walls, common walls and the flooring and floor framing in any lift pit, must be non-combustible; and

4. TYPE B FIRE-RESISTING CONSTRUCTION

4.1 Fire-resistance of building elements

In a building required to be of Type A construction-

a) each building element listed in Table 3, and any beam or column incorporated in it, must have an FRL not less than the listed in the Table for the particular Class of building concerned; and

b) the external walls, common walls and the flooring and floor framing in any lift pit, must be non-combustible; and

5. TYPE C FIRE0RESISTING CONSTRUCTION

5.1 Fire-resistance of building elements

In a building required to be of Type C construction-

a) each building element listed in Table 5, and any beam or column incorporated in it, must have an FRL not less than the listed in the Table for the particular Class of building concerned; and

b) the external wall that is required by Table 5 to have an FRL need only be tested from the otuside to satisfy the requirement; and "

8. As there are a lot of TYPE A and B buildings constructed by HB - we have a lot of requirements for non-combustible external walls as DTS or alternative solutions as the case may be

9. Consider that a type C construction may require non-combustible claddings contractually as ‘fit for purpose’ – separate to NCC compliance which may be achieved with a lesser standard than what sensibly may need to be used as a client minimum standard for example.

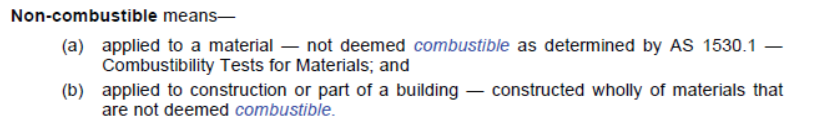

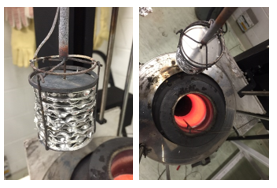

10. The NCC definition for non-combustible is referenced in the definitions section which requires all materials to be tested in accordance with AS 1530.1 for combustibility.

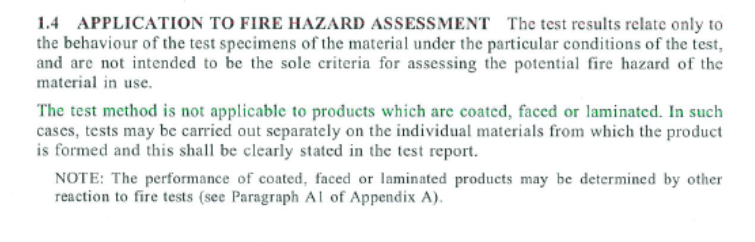

Testing to AS 1530.1

11. Particularly relevant to ACP/ALP is C1.12;

a. AS1530.1 states it’s not suitable for laminated products

– so under C1.12 the NCC provides an exemption to recognise certain ‘Bonded Laminated Panel’s as non-combustible – meaning it can be tested as the non-glue components only – ie the alum facing panels and the aluminium core

The following materials, though combustible or containing combustible fibres, may be used wherever a non-combustible material is required:

a) Plasterboard

b) Perforated gypsum lath with a normal paper finish.

c) Fibrous-plaster sheet.

d) Fibre-reinforced cement sheeting.

e) Pre-finished metal sheeting having a combustible surface finish not exceeding 1mm thickness and where the Spread-of-Flame Index of the product is not greater than 0.

f) Bonded laminated materials where-

i) each laminate is non-combustible; and

ii) each adhesive layer does not exceed 1mm in thickness; and

iii) te total thickness of the adhesive layers does not exceed 2mm; and

iv) the Spread-of-Flame Index and the Smoke-Development Index of the laminated material as a whole does not exceed 0 and 3 respectively

thickness of glue (ie 2 layers of 1mm max thickness glue) - which is essentially Honey comb type ACP panels and ALP …..the NCC permits these forms of panels to be tested without the glue - and of course they pass and are deemed ‘non-combustible’.

c. This section also nominates a few materials that are deemed non-combustible elements like Fibre cement (ie doesn’t need to be tested to AS1530.1 as its deemed acceptable)

12. The NCC also recognises a few things that are technically combustible but provides and exemption – like paint on a Fibre cement panel for example – the paint is exempt - refer C1.10(c) for the list of items

"C1.10 Fire hazard properties

a) The fire hazard properties of the following linings, materials and assemblies in a Class 2 to 9 building must comply with Specification C1.10;

c) The requirements of (a) do not apply to a material or assembly if it is -

i) plaster, cement render, concrete, terrazzo, ceramic tile or the like; or

ii) a fire-protective covering; or

iii) a timber-framed window; or

iv) a solid timber handrail or skirting; or

v) a timber-faced solid-core door or timber-faced fire door; or

vi) an electrical switch, socket-outlet, cover plate or the like; or

vii) a material used for -

A) a roof insulating material applied in continuous contact with substrate; or

B) an adhesive; or

C) a damp-proof course, flashing, caulking, sealing, ground moisture barrier, or the like; or

viii) a paint, varnish, lacquer or similar finish, other than nitro-cellulose lacquer; or

ix) a clear or translucent roof light of glass fibre-reinforced polyester if -

A) the roof in which it is insulated forms part of a single storey building required to be Type C construction; and

B) the material is used as part of the roof covering; and

C) it is not closer than 1.5m from another roof light of the same type; and

D) each roof light is not more than 14m2 in area; and

E) the area of the roof light per 70m2 of roof surface is not more than 14m2; or

x) a face plate or neck adaptor of supply and return air outlets of an air handling system; or

13. Products that have been tested to meet the AS 1530.1 non-combustible cladding definition are;

a. the honeycomb c ore type panels Vitracore G2, Larson A2

b. ALP – Aluminium laminated panels – such as Reynodual – which comprise 2 pieces of aluminium glued together as a laminated panel - ie these do not have a honeycomb type core.

c. ASP – Aluminium solid panels such as Vitradual and other solid panels such as zinc and copper

14. Products that are not AS 1530.1 tested such as Alpolic FR (Fire Resistant core), Alpolic A2, Alucobond A2, Kingspan PIR panels – as these don’t fit the exemption by the NCC on testing laminated products (because the adhesive/core is thicker than permitted by NCC C1.12) are tested to AS 1530.3 – methods for testing ignitability, flame propagation, heat release and smoke release. They may be very limited combustibility and suitable/safe for use – but they are not ‘non-combustible’ by definition so cannot be used as a ‘DTS’ solution.

15. The only way to use one of these products in TYPE A or B construction is using the performance assessment part of the NCC (Part A section A2.2) – where a suitably qualified fire engineer/certifier/ building surveyor determine that the use of a product that isn’t AS 1530.1 is still suitable for use – which needs to be documented as an assessment by the certifier/building surveyor using Assessment methods of the NCC which includes;

The following Assessment Methods, or any combination of them, can be used to ddeetermine that a Performance Solution or a Deemed-to-Satisfy Solution complies wiht the Performance Requirements, as apropriate:

a) Evidence to support that the use of a material or product, form of construction or design meets a Performance Requirement or a Deemed-to-Satisfy Provisions as described in A2.2.

b) Verification Methods - such as -

i) the Verification Methods in NYCC; or

ii) such other Verification Methods as the appropriate authority accepts for determining compliance with Performance Requirements.

c) Expert Judgement

d) Comparison with the *Deemed-to-Satisfy Provisions.

a. A0.5 (a) with reference to A2.2 Evidence of suitability assessment, the provision of CODEMARK certificates which confirm the products use is acceptable in certain circumstances (it’s important to read exactly what the certificate permits though) – so everyone can rely on it rather than everyone having to do their own special assessment for conformity to the NCC every time they want to use a product.

Noting there are published limitations on the products covered by the Codemark certificate – which means a Fire engineers really needs to review these

b. A0.5 (d) Expert judgement by documenting the solution in an FER (Fire Engineering Report) - usually an experienced and qualified fire engineer

"C10 Accredited certifier - fire safety engineering compliance

Issue of compliance certificates for alternative solutions involving fire safety for designs of and constructed building works certifying compliance with the relevant performance requirements of the BCA.

However, this does not include carrying out of any inspections required on such occasions as are prescribed by the regulations under section 109E(3)(d) of the EP&A Act.

Alternative solutions involving fire safety includes alternative solutions relevant to:

- fire safety systems and components of fire safety systems;

- the safety of persons in the event of fire;

- the prevention, detection and surpression of fire."

16. This may also trigger an approval by the Fire brigade in many cases as well (as they need to ensure anything that may affect their ability to fight a fire and as per section CP9 of the NCC)

Access must be provided to and around a building, to the degree necessary, for fire brigade vehicles and personnel to facilitate fire brigade intervention appropriate to -

a) the function or use of the building; and

b) the fire load; and

c) the potential fire intensity; and

d) the fire hazard; and

e) any active fire safety system installed in the building; and

f) the size of any *fire compartment.

17. Ultimately the Certifiers final occupancy certificate/certificate of classification needs to state the performance solutions (referred to as an alternative solution – see section 7 of a Form 11 for QLD – other states have similar requirements)

18. Note that there are restrictions to the use of combustible products at specific areas like fire exits per Specification C1.1 Clause 2.4 (usually fire engineers/certifiers/building surveoyrs deem this to be within 3m of the exit door in the external wall)

a) A combustible material may be used as a finish or lining to a wall or roof, or in a sign, suncreen or blind, awning, or other attachment to a building element which has the requiredFRL if -

i) the material is exempted under C1.10 or compiles with the fire hazard properties prescribed in Specification C1.10; and

ii) it is not located near or directly above a required exit so as to make the exit unusable in a fire; and

iii) it does not otherwise constitute an undue risk of fire spread via the facade of the building.

b) The attachment of a facing or finish, or the installation of ducting or any other service, to a part of a building required to have an FRL must not impair the required FRL of that part.

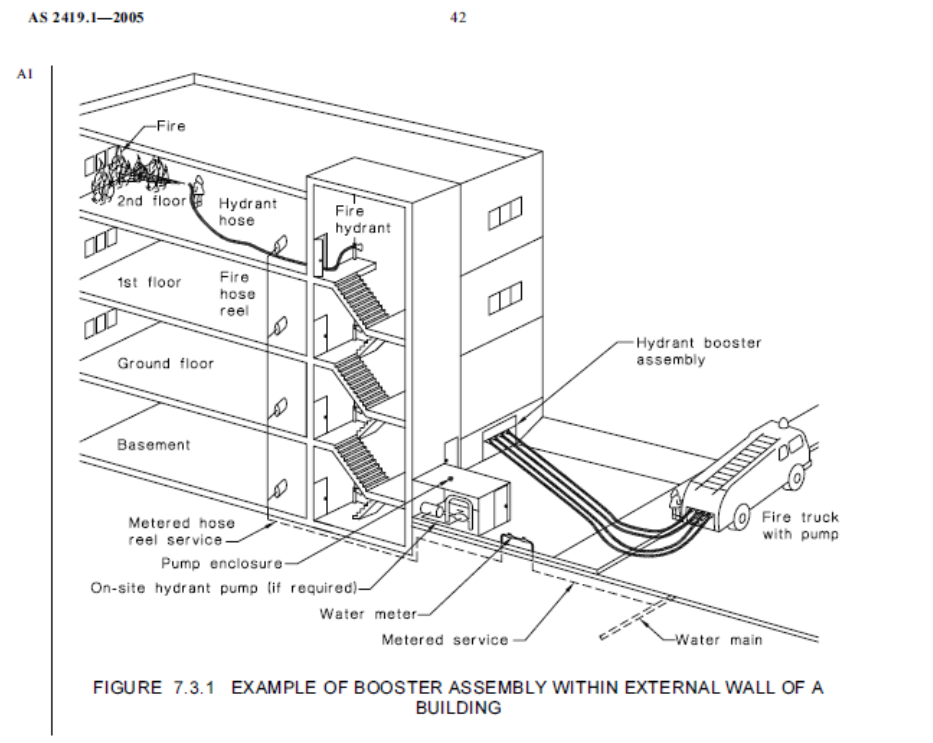

and special fire services like Hydrant boosters (refer AS 2419) – so in any performance solution the FER needs to confirm what’s required in these locations to meet CP2 (a)(i)

7.3 LOCATION

Fire brigade booster assemblies shall be located so that they meet the following requirements:

a) They are readily accessible to firefighters.

b) They are operable by fire brigade pumping appliances located within 8m.

c) If within, or affixed to, the external wall of the building, the booster shall be-

i) within sight of the main entrance to the building; and

ii) separated from the building by a construction with a fire resistance raiting of not less than FRL 90/90/90 for a distance of not less than 2 m each side of a 3 m above the upper house conections in the booster assembly.

NOTE: An example of a booster assembly within th eexternal wall of a building is shown in Figure 7.3.1.

19. All products considered for use must have the test reports/certificates/fire engineering reports available prior to use. They must be independent NATA approved testing companies that provide these test reports (Exova, CSIRO, Branz)

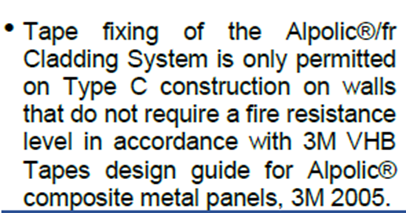

Ensure the report is valid and consider any ‘disclaimers’ or right to withdraw such as below where the document is an opinion of a product untested to a recognised AS (ie uses international testing + Fire engineers opinion to justify compliance in lieu of actually testing the product properly)

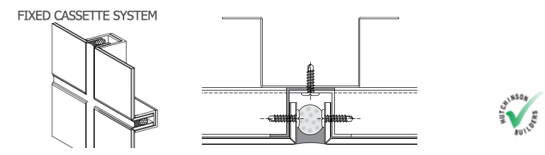

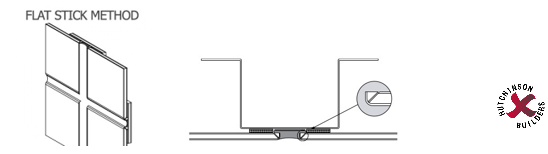

20. Its important to note that ACP/ALP products can be fixed in place in a number of ways – mechanically fixed ( screwed in place) or adhesive fixed (VHB –very high bond adhesive tape)

a. In TYPE A and B construction the products are required to be mechanically fixed – called ‘Fixed Cassette’.

b. Adhesive fixed only does not perform in fire, whereas mechanically fixed is screwed in place which prevents the panel falling off in a fire.

DON’T use this method unless Team Leader/Qualtiy Team have approved

c. Refer to the CODEMARK certificate for details of each product installation requirements as tested/verified/certified – extract from copy of Codemark Certificate above

21. In respect to the use of sarking and insulation behind the cladding – this is required to be;

• TYPE A & B per C1.1 3.1(b) and 4.1(b) the sarking/insulation cannot be less than the wall cladding itself which is non-combustible so the sarking must be non-combustible tested to AS 1530.1

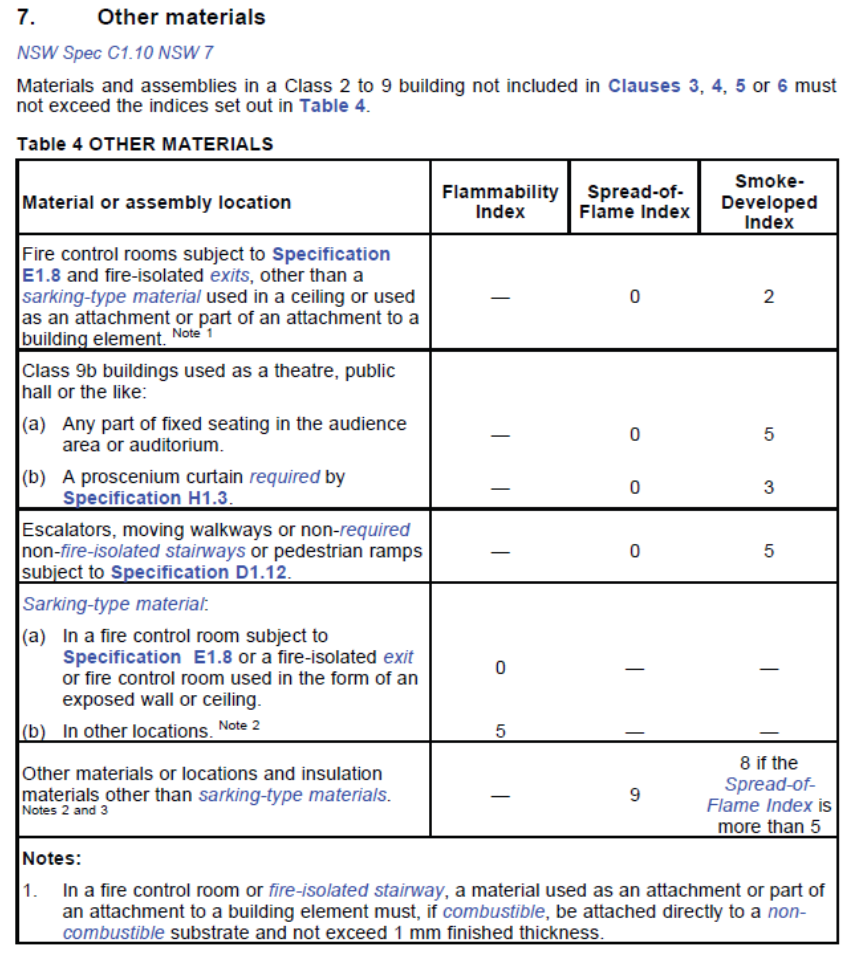

• TYPE C construction must meet the requirements of Specification C1.10 (a) (vii), and (ix) and tested to AS1530.2 for sarking and AS1530.3 for insulation

C1.10 Fire hazard properties

a) The fire hazard properties of the following linings, materials and assemblies in a Class 2 to 9 building must comply with Specification C1.10.

i) Floor linings and floor coverings.

ii) Wall linkings and ceiling linings;

iii) Air-handling ductwork;

iv) Lift cars.

NSW C1.10(a)(v)

v) In Class 9b buildings used as a theatre, public hall or the like -

A) fixed seating in the audience area or auditorium; and

B) a proscenium curtain required by Specification H1.3.

vi) Escalators, moving walkways and nonrequired non fire-isolated stairways or pedestrian ramps subject to Specification D1.12.

vii) Sarking0type materials.

viii) Attachments to floors, ceilings, internal walls and the internal linings of external walls.

ix) Other materials including insulation materials other than sarking-type materials.

Fire hazard properties means the following properties of a material or assembly that indicate how they behave under specific fire test conditions:

a) Average specific extinction area, critical radiant flux and Flammability Index, determined as defined in A1.1.

b) Smoke-Development Index, smoke development rating and Spread-of-Flame Index, determined in accordance with Sepcification A2.4.

c) Group number and smoke growth rate index (SMOGRArc), determined in accordance with Specification C1.10.

Flamability Index means the index number as determined by AS 1530.2

Smoke-Development Index means the index number for smoke as determined by AS/NZS 1530.3.

Sarking-type material means a material such as a reflective insulation or other flexible membrane of a type normally used for a purpose such as water proofing, vapour proofing or themeral reflectance.

Reflective insulation means a building membrane wiht a reflective surface such as a reflective foil laminate, reflective barrier, foil batt or like capable of reducing radiant heat flow.