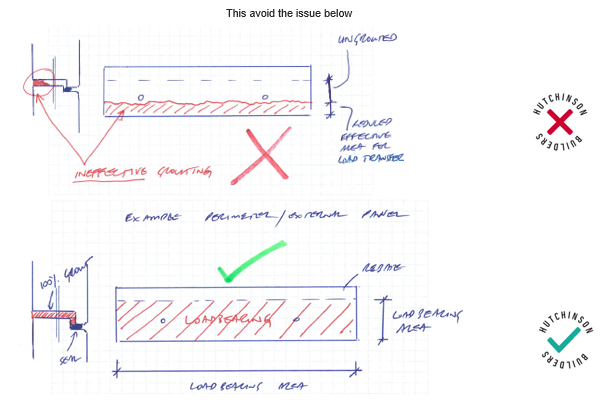

Reference to the below methodology and manufacturers requirements.

The critical part of web bed is ensuring there is a form of some description to push the wet bed against, and for the installers to ensure once the panel is propped to ram the grout into the space and compact. This is to ensure full depth of grouting is achieved without slump of the grout or voids forming.

Grouting Preparation Notes

From Parchem's "Filling the Gap, a Practical Guide to Grouting".

Pre-Soak The Substrate - one step in process of installing cement based grouts which is often overlooked is presoaking the concrete foundation before applying cement based grout. This simple step can have a dramatic effect on the outcome. This only applies to cement based grouts; do not pre-soak when using resin based grouts.

Once the formwork is in place and my sealant applied had cured sufficiently, the formwork should be filled with clean potable water for a minimum of 2 hours, preferably 24 hours, before the grout is applied.

Mixing - Correct mixing of the grout is critical to the success of a the total job. Sufficient man power and suitable equipment are essential.

Cement Based Grouts - the water to cement ratio in cement based grout is critical to the strength achieved and to the consistency required for the application. Water must be of drinkable quality (potable) and must be accuraately measued in line with the manufacturer's guidelines. NEVER exceed the manufacturer's recommended maximum water addition. The water should always be poured into the mixing vessel first then the grout powder added while mixing progresses, mixing time should be monitored with a stopwatch or clock to ensure sufficient time for the additives to begin working to produce the required final product - generally in the range of 3 to 5 minutes once all the powder has been added.

Batching - a single precast element is to be grouted using grout prepared in the same batch.

EXAMPLE 1

Install dowels - the use of ‘donuts’ (compressible seals) are only to retain the liquid grout used in the precast/dowel connection. Ensure the engineer is aware of this if you intend using them.

Installed Dowels - the use of "donuts" (Compressible seals) are only to retain the liquid grout used in the precast/dowel connection. Ensure th engineer is aware of this if you intend to use them.

Install leveling shims, wet the substate as per grout manufacturers requirements.

Wet bed the area for the precast element - consider measuring the expected volume of grout and checking againt the actual used.

Remember the water content affects grout strength - make sure the person mixing it understands the importance of strictly following the grout manufacturers instructions.

Lifting into position with exclusion zone.

Secure Bracing

Install fixings - noticng dust extration to be used.

As can be seen below, the panel once sitting on the shims, has some minor free play on the chains at the top meaning the precast can rotate (sway) a little back and forth – this action compresses the wet bed towards the outer edge – this can only be corrected by essentially ‘ramming’ the grout into the to the area once the panel is secured, chains removed and it cannot move again

Here you can see the grout has been forced out from under the panel both excess grout AND the sway of the panel as noted above

With the precast braced, ram the grout under the precast to ensure full depth and tidy up excess grout

EXAMPLE 2